14.nozzles of laser cutting head play an important role in laser cutting procedure–Ella

XLASER-Introduction of Laser Cutting Head Nozzles

1.nozzles of laser cutting head play an important role in laser cutting procedure

The function and adjustment of nozzles

a) design of nozzles and nozzles flow situation will affect the cutting quality;

the manufacturing precision of the nozzles is also closely related to the cutting quality.

b)The function of nozzle as following:

▲Prevent the cutting slag bounce up into the cutting head to damage the focusing lens.

▲The ejected situation of cutting gas can be changed by nozzle.

Nozzle can control the area and size of gas diffusion, then affect the cutting quality.

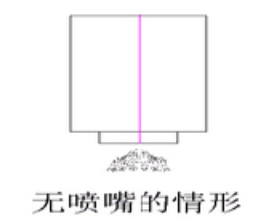

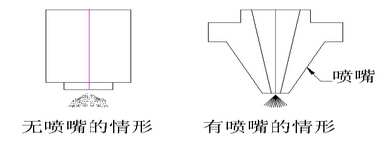

The following photo is 2 different situations of ejected gas,the left photo-without nozzle, the right photo-with nozzle.

Without nozzle With nozzle

2.Steps of adjusting laser beam through out from the center of nozzle

Comparing with CO2 laser cutting machine, fiber laser cutting machine has no light path.

We just need adjust the laser beam of nozzle.

Firstly,painting ink-pad on the surface of nozzle(ink pad or tape, only need choose one of them),

then paste white sticker on the surface of nozzle.

Secondly,adjusting the laser source output power at 30W-50W,start the mechanical optical shutter,

then quickly switch electronic optical shutter one time to observe the situation.

Next turn off the mechanical optical shutter, and take off the white sticker,

be careful not to rotate their relative positions.

If the distance between nozzle position and laser center is too large, the adhesive sticker will not play a central hole;

due to the laser center is fixed, we can change the center of the nozzle by adjusting the adjustment screw

on the handle of cutting head to let nozzle corresponds to laser center.

Repeat the above-mentioned operation until the center of nozzle coincide with the hole

which played on a white sticker, so as to confirm laser center coincide with the center of nozzle.

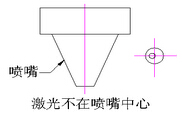

As the following photo:

Left photo: laser beam at the center of nozzle(Laser is in the center of nozzle).

Right photo: laser beam isn’t at the center of nozzle(Laser is not in the center of nozzle).

3.The impact of nozzle to cutting quality and the selection of nozzle aperture diameter

The relationship between nozzle and cutting quality:

When the center of the nozzle is different from laser center, the effect for cutting quality as following:

a)Affecting the cutting:

Because of uneven gas ejected, the cutting result will be one side with melt slag

while the other side does not have the phenomenon.

When it cuts metal sheet less than 3mm, the effect is smaller than cutting more than 3mm sheet, sometimes can not be cut.

b)Affecting the sharp corner cutting quality.

When cutting sharp corner work-piece or small angle of the work piece,

it will be more easier to appear local excessive melting phenomenon, sometimes can not be cut.

c)Affecting the ability of perforation.

It will happen perforation instability, the time is not easy to control,

causing excessive melting phenomenon for thicker steel sheet,

and the the conditions of penetration is difficult to master, while less impact on the thin metal sheet.

In summary, the concentricity between nozzle and the laser is one of the important factors

of causing the good or bad result of cutting quality, especially when cutting thicker metal, its impact is larger.

Therefore, we must adjust the concentricity between nozzle center and the laser nozzle to get better cutting result.

Notes: When nozzle is deformation or appear melt stains on the nozzle,

its impact on the cutting quality is same as above mentioned.

Therefore, the nozzle should be carefully placed in order to avoid its distortion;

melting stained stains on the nozzle should be cleaned promptly.

The quality of the nozzle at the time of manufacture already have higher accuracy requirements,

also it has the correct installation way.

If users need change many cutting conditions due to nozzle poor quality, the nozzle should be replaced.

4.The selection of nozzle

nozzles of different diameter.

| The diameter of nozzle | Gas flow rate | The ability of clean melt |

| smaller | Faster | Stronger |

| larger | slower | Weaker |

The diameter of nozzle includes φ1.0mm、φ1.4mm、φ2.0mm、φ2.5mm、φ3.0mm etc.,

common nozzle: φ1.4mm、φ2.0mm. As following photos:

left 1.4mm nozzle right 2mm nozzle.

The difference of those 2 types nozzle:

1) below 3mm sheet plate: Use φ1.4mm, the cutting surface will be fine;

using φ2mm, cutting surface will be thicker, the cutting corner will be have melt stains easily.

2) More than 3mm sheet plate: due to higher cutting power, cooling time is relatively longer,

also the cut time is relatively grow. Withφ1.4mm, gas diffusion area is small,

so it is not very stable when cutting, but it is okay.

Withφ2mm, gas diffusion area is larger, the gas flow rate is slow, so it is stable when cutting.

3)φ2.5mm nozzle only be used for more than 10mm thick plate.

In summary, the nozzle diameter has serious impact on cutting quality and the ability piercing quality.

Frequently-used nozzle diameter isφ1.4mm and φ2mm.

NOTES: The larger diameter of the nozzle, the worse ability of protection for the focusing lens.

Because sparks splash when cutting, there is a big chance to bounce up to focusing lens,

so the shorter the life time of the focusing lens.

If you want to learn more about laser cutting machine,feel free to contact us anytime.

Contact: Ella Guo

Whatsapp:+86 186 6968 5950

Email: xintian120@xtlaser.com