The function of pheumatic clamping system inside fiber laser cutting machine-Joey

Why pneumatic clamping system is needed inside precision cutting?

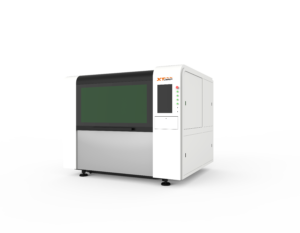

Inside of precision fiber laser cutting machine, there is a Pneumatic Clamp System. What is this all about?

The pneumatic clamping system has three functions. Opening and closing the mold, ejecting the plastic part, and sufficient force . To keep the mold close during injection to resist the pressure of the melt in the mold.

The clamping force required projected area of the part is usually 30 to 70 MPa (approximately 2 to 5 t / in2). The pressure generated during filling and force on the core due to the shrinkage of the part. It may cause the part to stick, resulting in two difficulties in separating half molds.

The initial opening force depends on the filling pressure, the dimensions of the material parts (depth and release angle). And is approximately equal to 10% to 20% of the nominal clamping force.

- Hinge or toggle clamping device: This design uses the mechanical properties of the hinge to provide the clamping force during material injection. The closing and opening speed of mechanical toggle clamping is fast, and the cost is lower than other clamping devices. The main disadvantage is that the clamping force cannot be precisely controlled. For this reason, it is only suitable for small machines.

- Hydraulic clamping devices: They use hydraulic pressure to open and close the clamp and generate the clamping force during material injection. The advantages of this design type are high reliability and precise control of clamping force. The disadvantage is that the hydraulic system is relatively slow and expensive when comparing to the toggle clamping device.

After you open the mold, the plastic parts tend to shrink and stick to the mold core , and must demold by the ejector plate provide by a mold system.

The pneumatic dot peen marking machine-Angelina