Automatic Production working on the Fiber Laser Cutting Machine: Steven

Automatic Production working on the Fiber Laser Cutting Machine

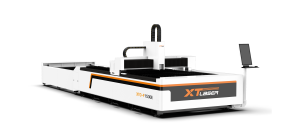

Fiber Laser Cutting Machine with the Exchange Platform.

Nowadays automatic production become more and more popular, due to it’s benefit. Firstly, It can save the expenses of labour. In many countries, expenses of labour are increasing, because of the currency inflection and population loss. It makes expenses of labour, become to a main point of enterprise’s existences. Also with the automatic production, enterprises do not need to spend to much time to managing labour. Thirdly, automatic production also can help expenses to reduce production time. It makes the entrepreneurs easy to manage the production time, facing the contract deadline.

XTC-F1530E is a model of Fiber Laser Cutting Machine with Exchange Platform. Exchange Platform can help the industry producer to prove their automatic production. Working platform can be changed by the control system. After the control system set up, workers do not need to wait for the machine finish it’s production, they can just load a new material. When the machine finish it’s production, the product and new material will change place by the control system. During the next production time, workers can lay off the product and up load anther material. Therefor the machine can be work all the time, it do not need to wait for the workers lay off and up load.

XTC-F1530E with 1500*3000’s body, and a changeable Fiber Laser Source. It’s body is made by pipe welding lathe bed, it’s quite sable and easy to fix. The Fiber Laser Source can be changed form power 1kw to 4kw, and the brand between IPG, Raycus and MAX. This Machine also has been step up with many high qutity parts, such as FUJI’s driver, Alpha’s reduction box and BAICHU’s contral system.

Email:xintian166@xtlaser.com

Whatsapp :+8617736997669