Considering our customers’ concerns, i ‘d like to share with you some features and operation cost of the handheld fiber laser welding machine. This machine is easy to operate and the maintenance cost is also very low.

*1.No need to install,can use directly.

There is no need to installation for the handheld laser welding machine,so our customers can use it directly after receiving the machine. It is very easy to operate,and there is no installation and training cost.

We have manual and operation video for our customers and also provide video call training, so that we can make sure that our customers can use this machine within 3 days.

*2.Less consumables:

The quickly-wear parts for the handheld fiber laser welding machine are only protective lens and copper nozzle.

And if you buy them from us, we can give you the cost price,

USD10 for copper nozzle(lifetime is 360 hours)

USD8 for protective lens(lifetime is 240 hours).

*4. Easy to maintain

The maintenance for this machine is very easy, when finish your welding work, then turn off the power and clean the welding head, it can make the lifetime of protective lens and copper nozzle longer.

*5.Power consumption

Except the quick-wear parts, the machine also consume electricity and gas.

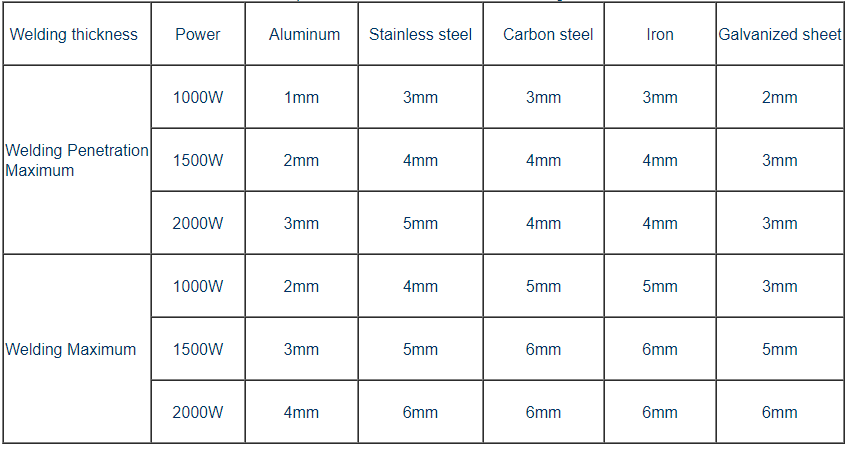

The power consumption of 1kw machine is 7.5kw-8.5kw/hour at full power situation. In fact, we usually just use 50%-60% power of 1000w to weld the metals, because it is enough, so the power consumption is small.

*6.Gas consumption

The machine also need to connect with gas, argon or nitrogen.

The gas can isolate the air from the welding plate to prevent the reaction with the air. So the welding surface of the metal plate will be white and beautiful. The gas also can protect the lens from welding dust.

Otherwise,The price of the gas is different in different counties and regions. If our customers think the cost of the gas is too high,then they can use air compressor to produce air gas. But the welding effect will not very good, the welding surface of the metal may be black, so our customers should wipe the surface of the metal with ethyl alcohol.

Hope it is helpful for you. If you have any confused of machine,please feel free contact us.

Wendy Liang

Email: xintian158@xtlaser.com

Whatsapp: 0086 19862161599

Website:www.xtlaser.com