Intelligent high-end, XT robot laser cutting machine drives the future!

Intelligent high-end, XT robot laser cutting machine drives the future!

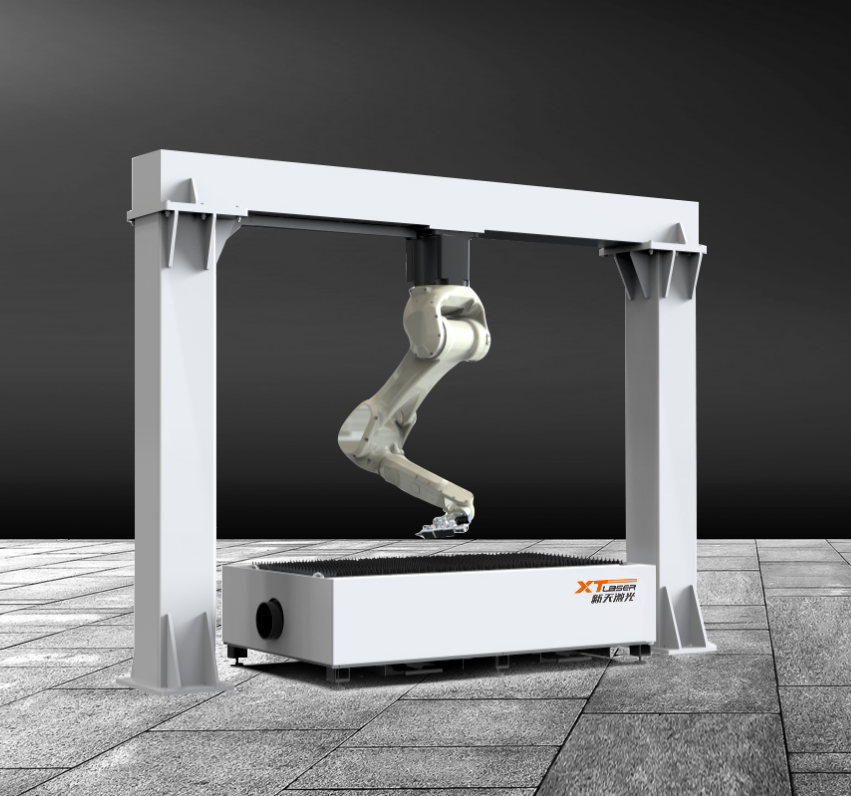

XT 3D Robot Laser Cutting Machine

Fully enclosed arm structure

Aluminum material with excellent performance

Ultra precise motion control

Displaying ultra-high precision dynamic performance

Perfect fit for laser processing application needs

Exquisite craftsmanship, exquisite details, and unique advantages

The XT 3D Robot Laser Cutting Machine is an intelligent laser cutting equipment that uses specialized fiber laser cutting heads, high-precision capacitive tracking systems, high-quality fiber lasers, and industrial robot systems to flexibly cut metal plates of different thicknesses from multiple angles and directions.

High speed precision cutting, 360 ° without dead angles

Gantry structure with large processing area ensures flexible movement of the cutting head; High precision six axis feed, 360 ° high flexibility cutting, maximum working radius 2010mm; Sensitive response and precise cutting, the laser head effectively cooperates with the robotic arm to avoid collision between the cutting head and the processed plate, ensuring accurate and stable cutting quality.

XY axis repetitive positioning accuracy Laser power load quality

Positive and negative 0.008mm, 1000W~3000W, axis 6, maximum load 20KG

Non contact machining, arbitrary cutting of 3D parts

The equipment is equipped with a fiber laser cutting head, a high-precision capacitive tracking system, a fiber laser, and an industrial robot system to perform multi angle and multi-directional flexible cutting of metal plates of different thicknesses, freely and flexibly realizing various complex 3D workpiece processing, and has good adaptability to complex surfaces.

Cutting samples

Integrating multiple scenarios to perfectly meet different processing needs

The 3D robot fiber laser cutting machine has a wide processing range and high work efficiency

Material used: cutting and processing of metal materials such as stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel plate, nickel titanium alloy, chromium nickel iron alloy, aluminum, aluminum alloy, titanium alloy, copper, etc

Applicable industries: aerospace, automobile and ship manufacturing, mechanical manufacturing, elevator manufacturing, advertising production, home appliance manufacturing, medical equipment, hardware, decoration, metal external processing services, and other manufacturing industries meet the metal cutting needs.

One machine with multiple functions, more cost-effective

Excellent beam quality:

Smaller focusing spot, finer cutting lines, higher work efficiency, and better processing quality

Higher cutting speed:

It is twice the power of a CO2 laser cutting machine with the same power

Higher stability:

Adopting world-class imported fiber lasers with stable performance

Lower maintenance costs:

No laser working gas; Fiber optic transmission without the need for reflective lenses; Can save a lot of maintenance costs

Convenient equipment operation and maintenance:

Optical fiber transmission, no need for complex Photosystem such as reflector, no need to adjust optical path, and no maintenance for external optical path

Visible Seiko Quality and Craftsmanship Power

160+global service outlets in export countries and regions

Creating localized and thoughtful service products for overseas sales

Providing 24/7 worry free service for 10W+customers with a firm choice

Worried about the strong research and development capabilities of after-sales service

30 minute rapid response to overseas quality certifications such as CE, FDA, SGS, etc

Engineer 1V1 Professional Services Assist in Industrial Intelligence Upgrade

Quality first, precision and transparency, rigorous control, and craftsmanship of high-quality products. XT Laser has been working in the laser field for decades, focusing on the core needs of users, thinking about what customers want and providing them with what they need, always putting users first. With meticulous and refined details, we present you with the increasingly perfect laser kinetic energy, empowering every day in the future.