Which brand is the best for metal laser cutting machine

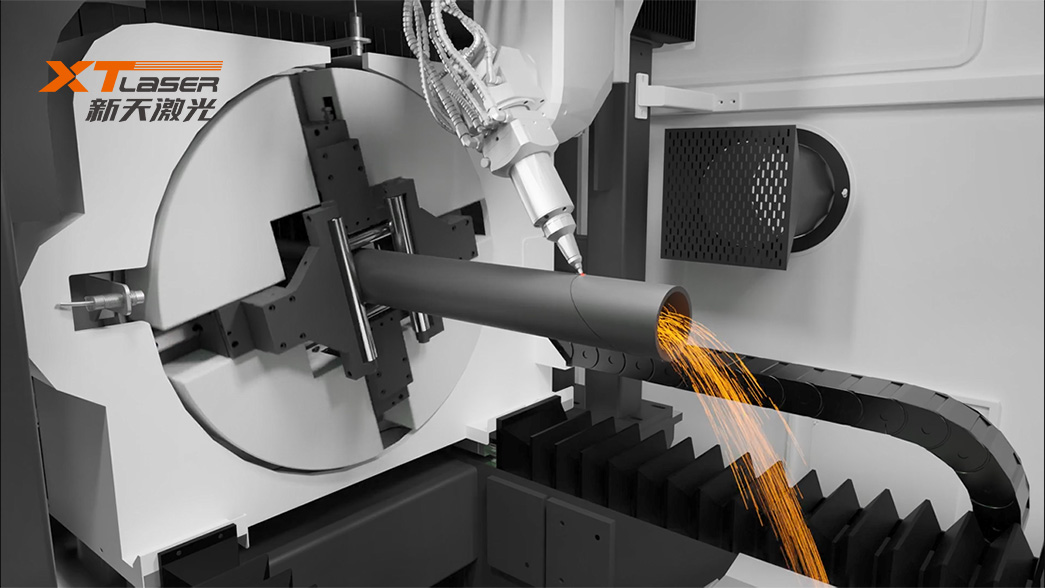

Plate and tube integrated laser cutting machine produced by Xintian laser cutting machine manufacturer

There are so many laser cutting machine manufacturers in the market, which one is the best laser cutting machine manufacturer. Which laser cutting machine brands are worth recommending?

Laser cutting machine is a kind of equipment used in factories. When buying, you should consider whether it is safe to use and how effective it is. You can’t just look at the brand and choose it. Many brands of metal laser cutting machines are immature and of poor quality. In order to expand the market, some manufacturers have implemented a price war. In this way, both configuration and after-sales service will shrink, thus damaging the interests of consumers. Different brands of cutting machines are different, and each has its advantages and disadvantages. When selecting cutting machines, different buyers will consider from different perspectives and make corresponding decisions. In the early stage, you can check the telephone number of the laser cutting machine manufacturer online for preliminary communication. So how should we choose among the metal laser cutting machine manufacturers in so many industries? Next, Xintian Laser will give you some suggestions, hoping to help you. The selection and purchase of equipment mainly depends on the following points.

- Scope of enterprise requirements for materials and business

First of all, we should clearly consider our business scope, the thickness of cutting materials, which materials need to be cut, and other factors. Then consider the power of the equipment and the size of the workbench. At present, the power range of laser cutting machines on the market is between 500 watts and 12000 watts. Machinery manufacturers of general size can customize according to customers’ needs.

For some important parts of cutting equipment, special attention should be paid during the procurement process, especially laser cutting head, generator, servo motor, etc. It is necessary to distinguish whether they are domestic or imported, because these core components directly affect the cutting speed and accuracy of the equipment.

2、 Preliminary selection of laser cutting machine manufacturers

After specifying the requirements, we will first go to the market or the colleague who bought the laser cutting machine to check the performance and basic parameters of the machine. Then select several manufacturers with strong strength and favorable prices to communicate and make samples. Later, we will go to the manufacturer to have a detailed discussion on the price of the machine, the training of the machine and the payment method. - Main components of fiber laser cutting machine

Some important parts of the laser cutting machine will affect the overall performance of the machine. We also need to pay attention when purchasing. The laser generator, laser cutting head, servo motor, guide rail, water tank and other components directly affect the cutting speed and accuracy of the laser cutting machine, which needs to be observed.

4、 Selection of laser cutting machine accessories

Special attention should be paid to purchasing these accessories on your metal laser cutting machine. - Software system

Software system can be said to be the brain of laser equipment. Its quality is an important aspect that affects the use experience of the device. Whether it can be compatible with hardware and make it more and more valuable depends on this “brain”. - Optical instruments

Optics is the core of laser cutting machine. If light cannot be produced, laser equipment will lose its due value. There are many optical elements in the fiber laser cutting machine, and each lens must ensure its quality. - Consumable accessories

Consumable parts are not many, but also an important part. They complement the laser and can complete metal cutting, such as water cooler, nitrogen and oxygen.

5、 Operation performance of cutting equipment

Easy operation is an intuitive and important aspect for customers to choose equipment. It can train personnel to work in a short time, thus reducing the learning time and use cost of personnel.

6、 After-sales service of cutting equipment

Some problems will inevitably occur during the use of the equipment. At this time, timely and high-quality after-sales service is very important. Don’t only focus on the price factor of the manufacturer, but choose from the stability and performance of the equipment. Because in the subsequent use of the equipment, you will understand the importance of after-sales service for laser cutting machine manufacturers.

The above points are suggestions for selecting laser cutting machine manufacturers. I hope I can give some guidance to friends who are ready to buy equipment. When purchasing specific equipment, comprehensive consideration should be given. Choosing a capable manufacturer can not only make your equipment last longer, but also save costs.