Running cost of handheld fiber laser welding machine-Teresa

Running cost of handheld fiber laser welding machine

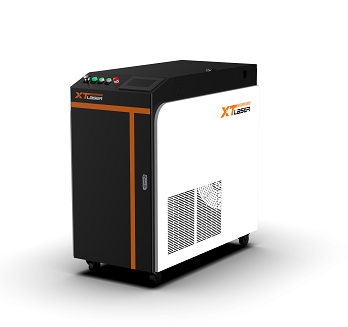

Nowadays handheld fiber laser welding machines are becoming more and more popular. Laser welding offers travel speeds that can be five to ten times faster than TIG welding and three to five times faster than MIG welding in some applications. It’s a good alternative to resistance spot welding in many applications. The main power includes 1kw, 1.5kw and 2kw. In this article XTLAZER will share the running cost of fiber laser welder with you.

Running cost of handheld fiber laser welder

The running cost of handheld fiber laser welding machine mainly includes 3 parts: power consumption, quick wear parts and auxiliary gas.

1. Power comsumption

In fact, we usually use 50%-60% power to weld the metals.

1kw total power consumption is 7.5kw. The real power consumption is only 3.8-4.5kw/h.

1.5kw total power consumption is 8.5kw. The real power consumption is only 4.3-5.1kw/h.

2kw total power consumption is 10kw. The real power consumption is only 5-6kw/h.

2. Quick wear parts

Quick wear parts for handheld fiber laser welder are only protective lens and copper nozzle.

Protective lens: lifetime is 240 hours, about 40-50pcs per year

Copper nozzle: lifetime is 360 hours, about 20-25pcs per year

Better environment, better operation, longer using time.

3. Auxiliary gas

The gas mainly plays a protection role, its consumption is very small. Nitrogen (N2) or Argon both are OK. But for materials easy to be oxidized, Argon is better. The gas can isolate the air from the welding plate to prevent reaction with the air. So the welding surface of the metal plate will be white and beautiful. The gas also can protect the lens from welding dust.

Hope these information can help you know more about fiber laser welder. If you want to know more, please feel free to contact us.

Email: xintian105@xtlaser.com

Whatsapp/ Wechat: +8615006829603

Skype: xtlaserTeresa