fiber laser cutting common problems and solutions-Serena

fiber laser cutting common problems and solutions

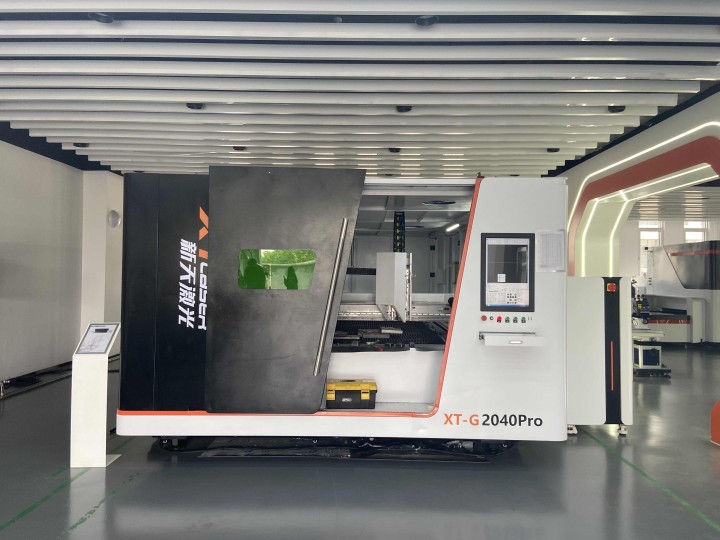

Fiber laser cutting machines are becoming more and more popular in metal processing and manufacturing. During use, various fiber laser cutting problems will occur. Such as laser head problems, electrical problems, laser problems, water-cooled machine problems, etc.XTLASER after-sales engineer sorted out many fiber laser cutting common problems and solutions.This article mainly explains electrical laser cutting problems.

Fiber laser machine is out of power

Cause of failure

1. Firstly,Phase sequence error

2. Secondly,The voltage is insufficient, the accessories are damage, and the circuit is not fasten firmly.

Solution 1: Firstly,Check the phase sequence and change any two live wires to change the phase sequence.

Solution 2: Secondly,Check the main power output , the fire and the live wire voltage. The three live wires and the neutral voltage respectively. Check the voltage of the phase sequence protection switch/three relays. The 220 behind the main AC contactor controls the pull-in voltage. And AC contact Whether the main line of the inverter is loose or whether the main AC contactor is burned out.

And more

The servo is out of power

Failure reason

1. Firstly,Emergency stop press

2. Secondly,switch is not turn on. Wiring is not fasten firmly. Switch position of different models is different. Please judge according to the model

3. Thirdly,Damaged accessories

4. Furthermore.Servo damage

Solution 1: See whether the emergency stop switch is turned on.

Solution 2: FL.GMAHM.AM detects whether the electric lock, servo switch, and the relay that controls the servo AC contact pull-in are energized (the wire number is generally 5 and 24V-),the upper control line of the AC contact is energized, and check it is wired If it is not connected properly, if the relay is on. You can replace it with other 24V relays to determine if it is good or bad, and see if the AC contactor is damaged

Solution 3: Opens the servo circuit breaker and there is electricity. Measure whether the circuit breaker has electricity and whether it is normal.

Solution 4: Whether the voltage of the electronic transformer is normal.

Solution 5: Replace the servo.

No power for laser water cooling

cause of issue

1. Firstly,The external switch is damage and the circuit is block.

2. Secondly,Internal problems of the water-cooled machine.

Solution 1: Firstly,Check the voltage at the terminal. The voltage of the circuit breaker. If the main power supply of the machine. The voltage stabilizer or the field voltage is normal,whether the switch is damage, replace the switch recovery circuit.

Solution 2: Secondly,Contact XT engineers