How can have a better effect when cutting round holes with laser cutter-Ariel

How can have a better effect when cutting round holes with laser cutter

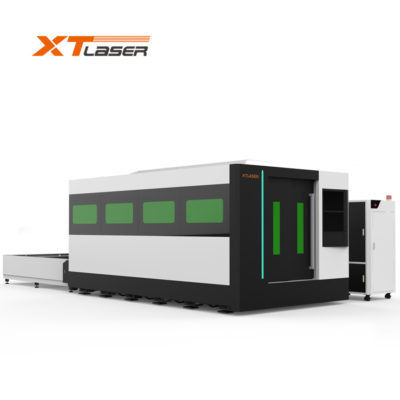

With the emergence and development of laser cutting machine, but also because of the low precision of traditional cutting technology, many burrs and other characteristics, more and more enterprises choose laser cutting machine to cut circular hole.So this article is about how can have a better effect when cutting round holes with laser cutter.

Laser cutting machine not only cutting surface smooth, and cutting speed is so popular.The following problem on cutting round hole to analyze the reasons and matters needing attention.

1.The hole is too small

Although the laser cutting machine cutting round hole is a satisfactory solution‘’But in fact, the larger the aperture, the better the cutting, when the aperture is too small, the cutting hole will appear irregular round hole, breakpoint residual too much phenomenon.

2.The gas pressure is too high or too low

Too much gas pressure will burst the hole, too little pressure will appear rough cutting edge, and serious burning.Therefore, choosing the appropriate cutting gas pressure is one of the reasons to solve the irregular cutting.

3.Servo motor parameters

Many parameters of the servo motor related to circular arc motion. Improper parameters will result in mismatching of x axis and Y axis motion. It will result in oval or irregular shapes when cutting round holes.

4.Lead screw or guide rail accuracy is not enough

Some cutting machine manufacturers have low manufacturing level and low configuration, resulting in the laser cutting machine accuracy of less than 0.1mm, so when cutting round hole accuracy is not up to.

So, you can look at the cutting hole to identify the quality of the laser cutting machine. And then choose a high quality cutting machine.

Ariel from XT LASER E: xintian122@xtlaser.com WhatsApp&Wechat&Mobile: +86 17866940010 Skype: Ariel XTLaser