304 stainless steel can be suitable for laser cutting+Karina

304 stainless steel can be suitable for laser cutting

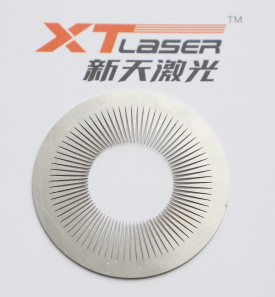

304 stainless steel can be suitable for laser cutting, laser cutting uses a focused high-power-density laser beam to illuminate a workpiece.

Causing the irradiated material to rapidly melt, vaporize, ablate, or reach a flash point.

While at the same time blowing the molten material by means of a high-speed air stream coaxial with the beam.

1. Good cutting quality and small deformation of the workpiece

The laser spot is small, the energy density is high, and the cutting speed is fast, so laser cutting can obtain better cutting quality.

Firstly, the laser cutting slit is narrow, the slits are parallel and perpendicular to the surface.

And the dimensional accuracy of the cut parts can reach ±0.05mm.

Secondly, 304 stainless steel laser cutting machine cutting surface is smooth and beautiful.

The surface roughness is only a few tens of microns, even laser cutting can using as the last process, no mechanical processing, parts can using directly.

Thirdly, After the laser cut by the laser, the width of the heat-affected zone is small.

The performance of the material near the slit almost unaffected, and the deformation of the workpiece is small.

The cutting precision is high, the geometry of the slit is good, and the shape of the slit cross-section is relatively regular, rectangular.

The cutting material is a 6.2 mm thick low carbon steel plate.

2, high cutting efficiency

Due to the transmission characteristics of the laser, the laser cutting machine is generally equip with multiple numerical control worktables.

And the entire cutting process can realize numerical control. During operation.

It is only necessary to change the numerical control program to apply the cutting of different shapes of parts, which can perform two-dimensional cutting and three-dimensional cutting.

3, cutting speed

Cutting a 2mm thick low carbon steel plate with a power of 1200W, the cutting speed can reach 600cm/min.

Cutting a 5mm thick polypropylene resin plate, the cutting speed can reach 1200cm/min.

The material does not need to clamp and fix during laser cutting, which saves the fixture and saves the auxiliary time of loading and unloading.

Contact people:Karina Xiao

Whatsapp:008618206584205