Things to Know Before Buying Fiber Laser Cutting Machine+Karina

Things to Know Before Buying Fiber Laser Cutting Machine

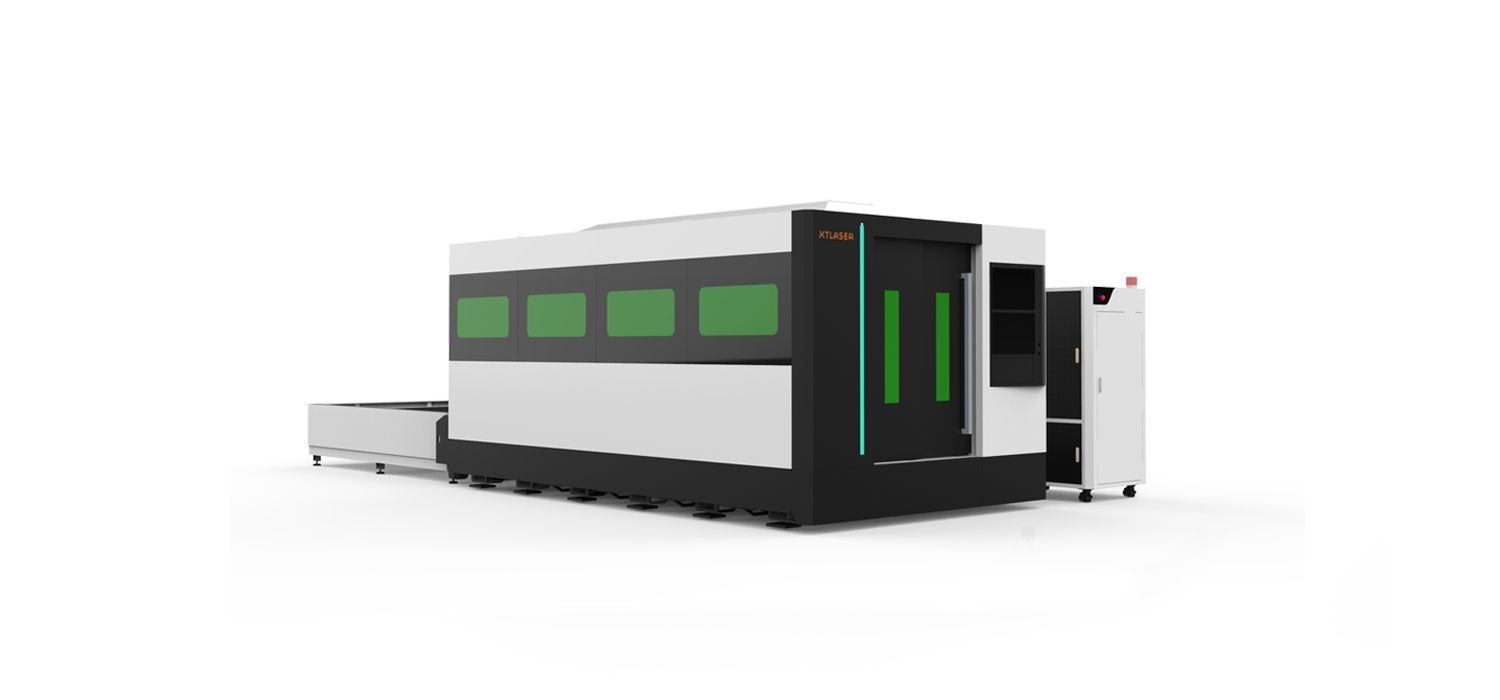

Things to Know Before Buying Fiber Laser Cutting Machine. Purchasing a fiber laser cutting machine is never a simple thing no matter whether you buy it from local suppliers or overseas suppliers.

Because it concerns the return your investment will achieve and the benefits your business will receive.

Before buying a fiber laser cutting machine, some things should consider to gain the maximum vale from your investment.

Why Choose Fiber Laser Cutting Machine?

Máquina de corte a laser de fibra is now increasingly used in metal processing industries.

It has highly powerful fiber laser beam that works on sheet metals with precise and efficient cutting performance.

The laser head won’t directly touch the surface of materials so that the cutting effect is completely protect.

The auxiliary cutting gas can be chose from oxygen and nitrogen, depending on what metal types you plan to work with.

The residues produce in the cutting process could blown out auxiliary cutting gas and collect in the waste collection box below the lathe.

Hence the total cutting process is clean and environmentally friendly.

When it comes to metal cutting, YAG laser, plasma laser, CO2 laser and fiber laser all are able to cut metals, but with different cutting thickness, speed, precision and efficiency.

The main differences lie in that YAG cut metals with higher electrical consumption, low efficiency and high maintenance cost; plasma can be use to cut sheet and thick metals.

And it especially works better on thick materials; CO2 laser cutting machine is also suitable for thick metals cutting with higher cost and not very high precision.

Fiber laser cutter is currently the leading laser cutting solution by virtue of its superior cutting accuracy (0.02mm/min), lower energy consumption, higher productivity and little maintenance.

How to Select a Fiber Laser Cutting Machine for Metals?

Materials

You should decide whether your materials involve steel tubes, for which we could configure an extra fiber laser tube cutting device for the laser equipment.

Also, if your materials contain highly reflective metals, such as silver, aluminum, red copper, etc.

We would recommend you nLIGHT laser source which is perfectly suitable for reflective materials processing.

Materials Size

Material size is also key to the fiber laser cutting machine selection.

It’s decide by the size of both the products you manufacture and workshop space.

You should take a careful measurement on them and then decide the size of work table or the lathe of fiber laser cutter.

Cutting Thickness

In order to achieve perfect cutting effect and work efficiency,

the thickness of material has to be match with the wattage of fiber laser cutting machine.

Also your intended productivity per day will help you choose the most

productive wattage which has direct influence on cutting speed.

Still, please note that different metals that have the same thickness require different wattage.

if you are now looking for fiber laser cutting machine, pls consider the above carefully!

Karina

Email: xintian103@xtlaser.com

Skype: xtlaser103

Wechat & Whatsapp;008618206584205