Jewelry processing is becoming more more automatic. Before people may process it by hand with knife, special screw, saw etc. Mow more and more people replace traditional tools with laser machine. as laser processing on jewelry is much more fast and precision, we can use it do many complex pattern and many hard work.

In jewelry manufacturing fields, fiber laser cutting machine, fiber laser marking machine and laser welding machine all have wide application.

-

Máquina de corte a laser de fibra

Small size high precision fiber laser cutting machine is very expensive. But it become more and more popular for some big jewelry manufacturer. Fiber laser cutting machine have very fast cutting speed and very high cutting precision for jewelry working. For one name necklace, few seconds it can finish it. Of course, due to usually we cut thin gold and silver sheet, it need special fixture. Other wise the sheet will be deformation during cutting as cutting process need blow auxiliary gas.

Additional, gold and silver belong to high reflective material. Its cutting need special laser soruce. The laser head also need do special structure. If you need know more details about it, you can send me message by email.

-

Fiber laser marking machine

Fiber laser marking machine should be the most popular laser machine on jewelry processing, we can use it both on marking and cutting. We can use any power laser machine on gold, silver, brass and other metal marking. The marking content like picture, pattern, letter, number and so on. Otherway we can use it on deep engraving and thin gold&silver sheet cutting. Now many people use it cut necklace, especally name necelace.

Add one rotary axis for fiber laser marking machine, also we can use it mark rings both inside and outside.

-

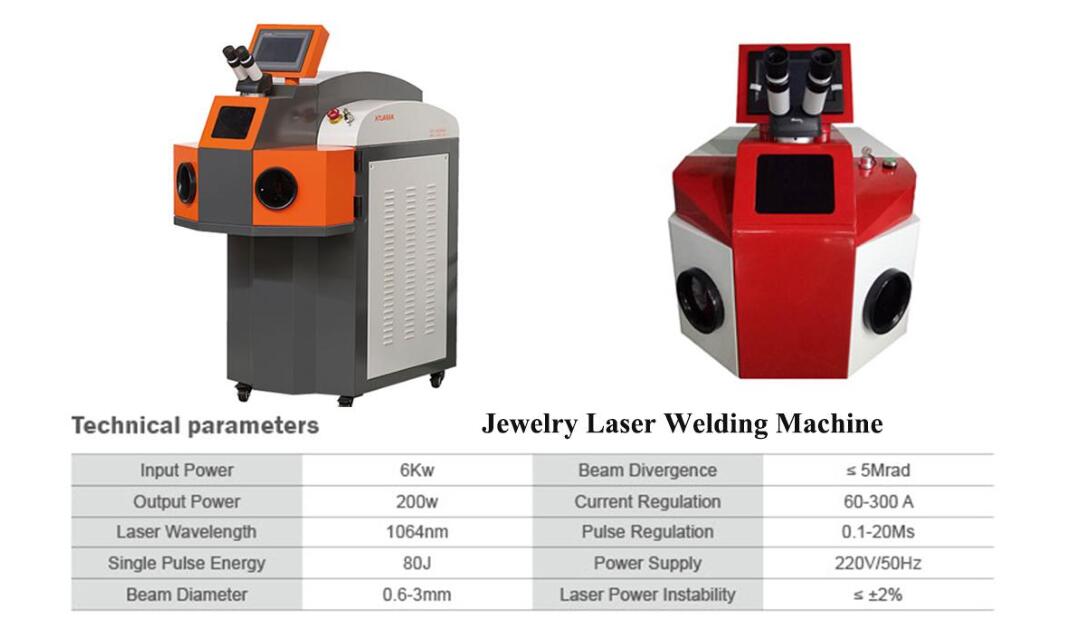

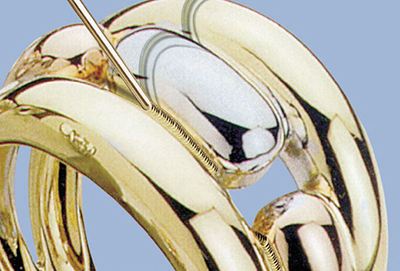

Laser welding machine

Laser welding machine should be the earlist laser machine which used on jewelry processing. For rings welding, reparing and chain manufacturing, it have good performance. Now there is special type especially used on jewelry welding.

If you want to learn more about laser machine, we can talk more.

Alex Wang

Email: xintian104@xtlaser.com

Mobile&whatsapp: 0086 18766152065

Skype: saint512406