Help you to know the laser cutting machine focus:Charry

Help you to know the laser cutting machine focus

Help you to know the laser cutting machine focus.

Firstly,Cutting the focus on the surface of the work piece.

This method also becomes a focal length of 0.When using, the focus of the cutting machine is select to be close to the surface of the work piece. In this mode, the smoothness of the upper and lower surfaces of the work piece is different. Generally, the cutting surface close to the focus is relatively smooth, and away from the cutting focus. The lower surface appears rough. This mode should base on the process requirements of the upper and lower surfaces in the actual application.

Secondly, cutting focus on the work piece.

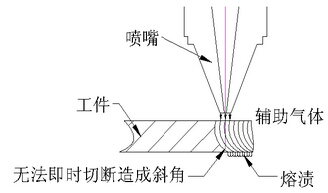

In this way we also become a negative focal length.Because the cutting point is not locate on the surface of the cutting material nor inside the cutting material.But rather above the cutting material. This method mainly uses materials with high cutting thickness.Because the slits require for the thick plates are large.Otherwise the oxygen delivery by the nozzles is likely to be insufficient. One disadvantage of this approach, is that the cut surface is rough and not very useful for high precision cuts.

Thirdly, the cutting focus is inside the work piece.

This method also becomes a positive focal length. When you need to cut a work piece that is stainless steel or aluminum steel.The pattern of cutting points inside the work piece is often used. However,there is one disadvantage of this method.The cutting surface is larger than the cutting point on the surface of the work piece.Due to the focus principle. At the same time, the cutting airflow required in this mode is large.The temperature is sufficient.And the cutting perforation time is slightly longer. Therefore, when the material of the work piece you choose is mainly stainless steel or aluminum material,you can choose this method.

The cutting effect is relate with the pressure,the speed,the focus.

If your cutting effect is not good,also need to think about other factors.Like gas pressure,cutting speed.

Sometimes the purity of the gas also affect the cutting.

If you want to know more,we can talk online.Or you can send questions by email.

Following is our contact info.

Email:xintian111@xtlaser.com

Whatsapp:+8618253165863