What is Fiber Laser Marking ? –Doris

What is Fiber Laser Marking? Let’s take a look in this informative blog post!

A wide variety of businesses rely on laser marking technologies to decorate, categorize, or identify the products that they make. Finding the quickest and most effective way to produce markings on a specific material is critical to maximizing efficiency for each company. Fiber laser marking is one of many ways to produce product markings, and is a critical method for many operations.

Providing an industrial solution for product identification and traceability, our Fiber Laser Marking Systems allow manufacturers to mark or engrave serial numbers, bar codes, 2D Data Matrix and graphics on the widest variety of materials, including metals, plastics and ceramics.

What is Fiber Laser Marking?

In short, fiber laser marking is one method of using lasers to place identifiable permanent marks on an object.

For Example:

You may have seen a laser engrave your pet’s name on their ID tag, or noticed the laser marked apple logo on the back of your iPod.

The method can be done on a range of materials, like plastics, metals, and ceramics. The practice does not involve the use of any stickers, ink, or tool bits by using the technique of laser engraving. Designs done by this method can be as intricate or as simple as desired, and due to the effect of carbonization, lasers are capable of marking some materials with colors.

How Fiber Laser Marking Works

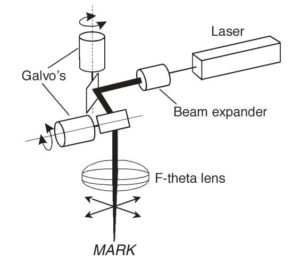

What is Fiber Laser Marking? In Short, if you’re still unclear, Laser marking is done by changing the surface properties of a material. To achieve this, a low to medium powered laser beam is moved across the surface of the object. The laser beam will heat the material and cause oxidation, which discolors the affected areas of the material. Then, as the material cools, the surface anneals and finalizes the change. This type of marking is done without indenting the surface of the material and will remain intact in all but the harshest conditions.

Laser engraving, similar to laser marking, is a process that uses a laser to remove the surface of a material and leaves behind an indented etching of text or design.

Fiber lasers are the newest of three popular types of lasers on the market. They are known for their ability to anneal stainless steel, and heat to temperatures that draw carbon to the surface of a material.

Fiber lasers also perform well on various materials, such as:

*Silver

*Bronze

*Gold

*Tungsten

*Leathers,

*Plastics

And More..

Uses of Fiber Laser Marking

This technique is primarily used for identifying marks such as bar codes, QR codes, and logos. However, laser markers are found in virtually every industry and have a wide variety of uses. This equipment is especially popular for labeling machine parts, item numbers, manufacturing locations, or product numbers. These machines can be used to categorize products or leave markings to match with an assembly guide. Lasers are also used decoratively to place designs on objects or personalized marks on jewelry.

Advantages to Consider

Fiber laser marking machines are known for the high quality of their markings. Laser marked designs are extremely sharp and precise, which will last for an extended amount of time without wearing or fading. There are no replacement costs as there would be for ink jets and worn tool bits, and designs can be placed in a variety of high-contrast colors with no extra cost. The machines take up a small amount of space, and are air cooled rather than water cooled. They are preferable to other types of lasers due to their simplicity, strength, and efficiency.

If need more information about fiber laser marking machine, contact us freely!

Attn: Doris

Email: xintian103@xtlaser.com

Skype: xtlaser103

Whatsapp: 008615990992073