Classification and selection criteria for metal laser cutting machines

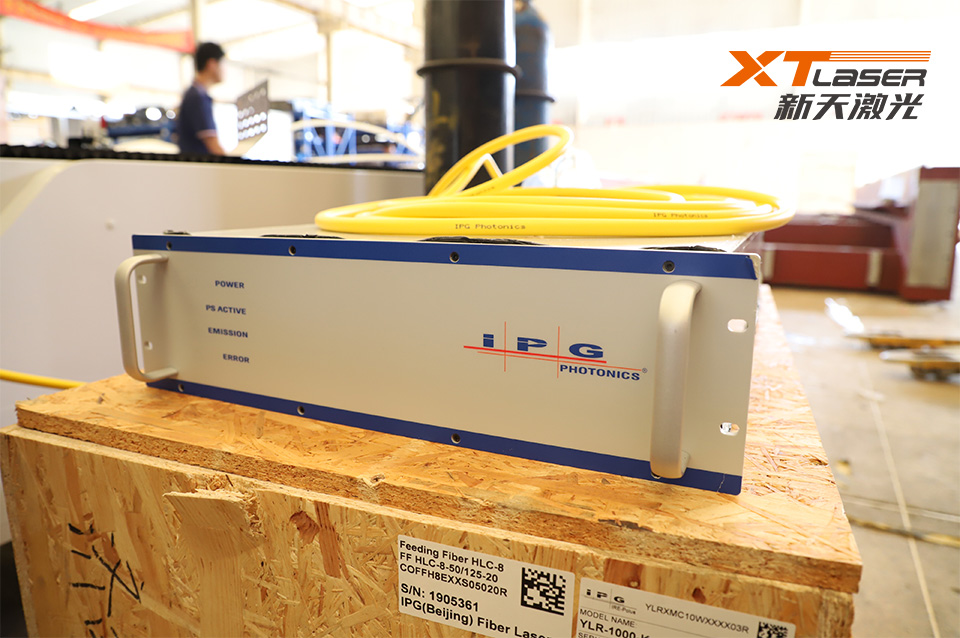

XT Laser-metal laser cutting machine

Metal laser cutting machine is a relatively common equipment in the metal processing production line, which is used for the production and processing of metal materials. How to choose a more suitable and efficient metal laser cutting machine has long been a concern of users. The following will give a detailed introduction to these problems.

Classification of metal laser cutting machines.

1. Flat metal laser cutting machine

The flat metal laser cutting machine is one of the laser cutting machine equipment, which is mainly used for two-dimensional cutting of flat plates. Most metal materials on the market are processed in a flat way, and it is also widely used. The flat metal laser cutting machine is divided into two types: single table and interactive. Generally, the single table has a high cost performance and interactive automation. It can easily meet the daily production needs of users of medium-sized and small production enterprises.

2. 3D metal laser cutting machine

Three-dimensional metal laser cutting machine is an upgraded new product of the general metal laser cutting machine. It is equipped with an automatic mechanical arm, which can rotate 360 ° to cut, and can process various curved metal materials. It has a good representation in the production efficiency and the display of the finished product effect, and is very suitable for various curved surface cutting and forming work.

3. Metal laser pipe cutting machine.

Metal laser pipe cutting machine is a kind of equipment capable of cutting various thin-walled metal pipes, such as stainless steel pipes, which is convenient and fast. At the same time, it also saves a lot of processing costs for users. Once sold, it has attracted many people’s attention.

The metal laser cutting machine replaces the traditional metal processing technology and occupies an increasing share of the market. Following the high demand standard of metal laser cutting machine quality, high-quality metal laser cutting machine technology is very critical.

The following four points should be noted when selecting metal laser cutting machine:

1. Environmental protection of metal laser cutting machine:

China’s environmental protection standards are very strict. A series of environmental protection policies have been issued, and a large number of processing plants that do not meet environmental protection standards have been closed. Therefore, when selecting the metal laser cutting machine, we must meet the national environmental protection standards and strictly control the dust and noise pollution.

Each metal laser cutting machine should be based on green environmental protection, with high production efficiency and energy saving as the goal, and establish a green, environmental protection, legal and sustainable metal laser cutting machine production line.

2. Quality quality of metal laser cutting machine

The quality of metal laser cutting machines on the market varies from high to low. The manufacturing materials of metal laser cutting machines affect the quality of metal laser cutting machines to a large extent. If the purchased metal laser cutting machine is of poor quality, frequent and major failures will occur in the process of use, affecting the production efficiency of the metal laser cutting machine.

3. Reputation of metal laser cutting machine

The reputation of the manufacturer of metal laser cutting machine reflects the quality and reputation of metal laser cutting machine. The reputation of metal laser cutting machine can help users understand the manufacturer of metal laser cutting machine in the early stage. The manufacturer of metal laser cutting machine with good reputation can ensure the equipment quality and the production process is more professional.

4. After-sales maintenance service of metal laser cutting machine

The after-sales maintenance service of metal laser cutting machine is the quality assurance of the production of metal laser cutting machine in the future. After-sales maintenance service is particularly critical. Generally speaking, formal metal laser cutting machine manufacturers have already established a professional team of installation technical engineers. After-sales maintenance service is also a point that many users tend to overlook. If the after-sales service is not timely, once the metal laser cutting machine has problems, it will be particularly cumbersome and cause production difficulties for users.

In addition to selecting the appropriate metal laser cutting machine, the quality of the equipment should be strictly controlled. The equipment will have great impact during operation, and parts will be damaged. Therefore, if the quality is not strictly controlled, the service life of the equipment will not be guaranteed. When selecting the metal laser cutting machine equipment, users should visit the manufacturer in person and compare the equipment quality of different manufacturers.