Automatic loading fiber laser tube cutting machine-ivy

Automatic loading fiber laser tube cutting machine

Today,am just received one inquiry of Automatic loading fiber laser tube cutting machine from Australia. So want to make some information here:

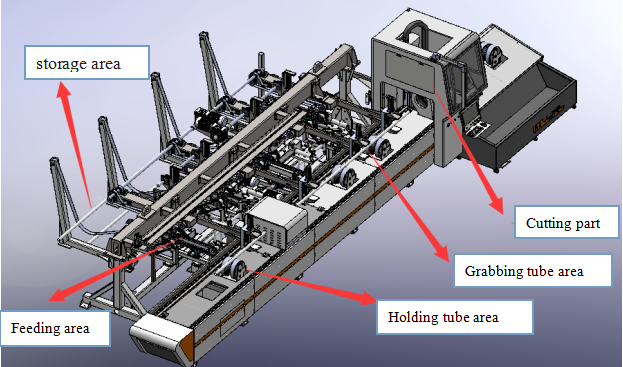

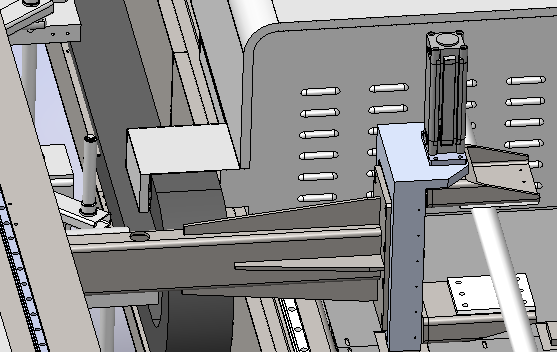

First one is design of Automatic loading:

Basic working processes:

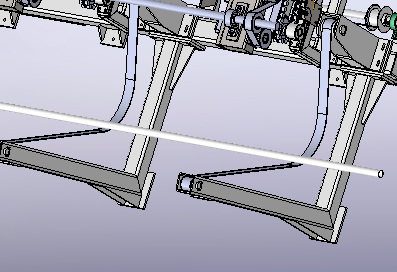

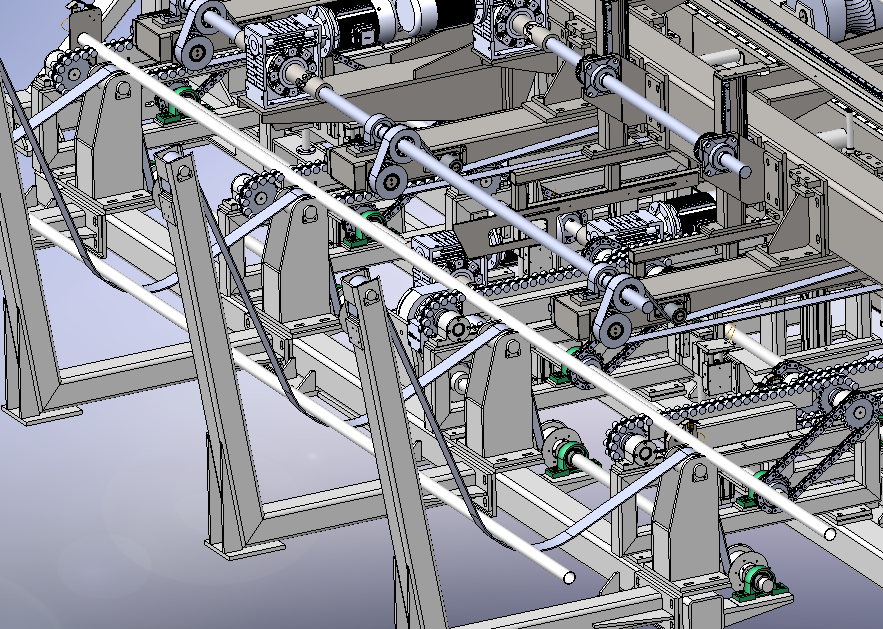

- First, put the same type pipe on the nylon belt of the storage area using a forklift or manually.

2.Then, the motor is driven by the nylon belt to send the pipe to the feeding area, and the conveying area sends the pipe to the grabbing position.

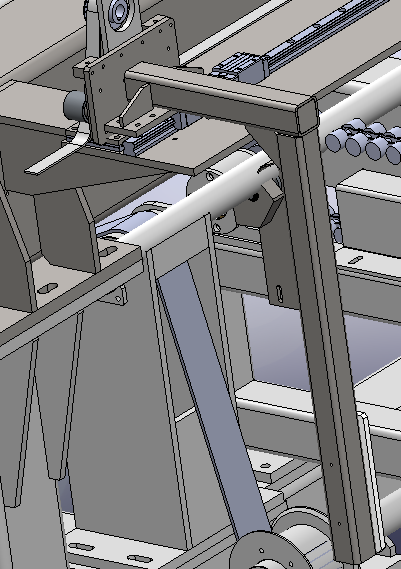

3.After reaching the grab position, align one end of the tube with a lever.

4.The gripper grips the tube then feeds the tube to the top of the palletizing device to prepare for chuck clamping.

5.The behind chuck move to the gripping position then clamp the tube.

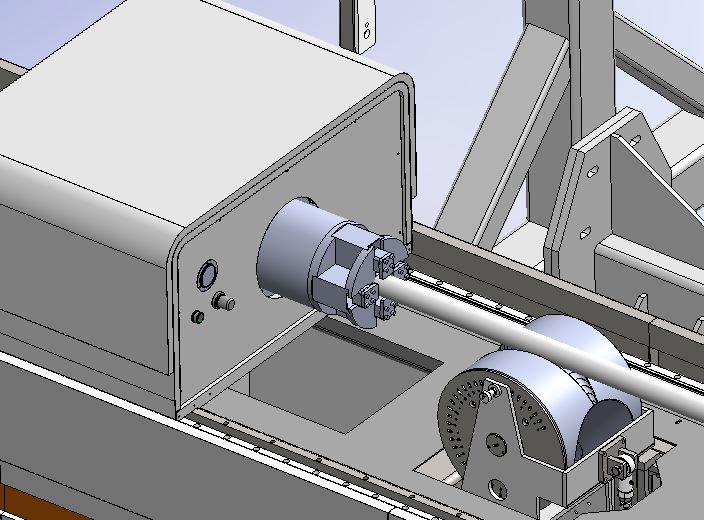

6.The chuck feeding tube to the cutting position then the cutting starts.

7.After first tube cut done, chuck return to Y axis home, the second tube starts to load.

The principal characteristics of the XTC-T60020 Fiber laser cutting equipment are:

- Compact design facilitating a wide variety of applications.

- CNC with laser control function.

- Resonator with reflective sensors.

- Simple program for pieces and cutting plans with automatically adapted feed speed and power output for each piece, using CNC.

- Highly dynamic equipment.

- Rigidity: high strength transfer due to stability of construction.

- Durability: enclosed drivers.

- Accessibility: spare parts service