Plastic laser marking ( 1 )- Elena

This section presents information that covers, from the principles of plastic marking and processing, to the advantages grouped by the laser wavelength. It presents examples of marking and optimal laser markers for a variety of materials such as ABS, epoxy and PET.

Types of plastic marking / processing

Peeled paint

Peel the paint or print on the surface of the object, to generate a contrast with the color of the base material.

- (Example) Car instrument panel switch

- When the design is changed, conventional methods that use printing or stamps require that the printing plate be changed. With a laser marker, this can be handled flexibly, changing only the program.

-

Surface peeling

Remove / etch the surface layer with a laser.

- (Example) Half cut

- Use a laser marker to process a section of cut. In the conventional method a cutter was used; however, there were problems such as adjustment difficulties and time-consuming changes between the types of products. In addition, the method introduced costs for the replacement of the blade and there was a risk that it would be left in the product.

-

Color development

Radiate the plastic object with a laser to develop a color in it.

- (Example) Wide area marking in LSI

- The use of a laser to irradiate the plastic in order to color it without engraving it, ensures minimal damage to the object during marking. In addition, you can mark areas of up to 330 × 330 mm, all at once, and reduce costs of mechanical equipment, thanks to the elimination of the need to transport the object, as with conventional methods.

-

Soldagem

Use the heat of laser radiation to weld and join plastic parts.

- (Example) Welding of transparent and colored plastic material

- While it is known that ultrasonic and vibration welding adversely affect products, and cause burrs due to fusion, laser welding is contactless and does not damage the product or cause burrs.

-

Mechanism of color development in plastics

Foaming

When the base material is irradiated with a laser, gas bubbles are generated within it, due to the thermal effect of the radiation. Evaporated or gasified bubbles are trapped in the surface layer of the base material, which creates a whitish swelling. These bubbles are particularly visible in dark base materials and result in a “thin” coloration.

Condensation

When the base material absorbs the laser energy, the thermal effect increases its molecular density. The molecules condense and the color changes to a darker color.

Carbonization

When the area continuously receives high energy, the macromolecules of the element around the base material carbonize and turn black.

Chemical change

The “pigment” elements in the base material always contain metal ions. The laser radiation changes the crystalline structure of the ions and the level of hydration in the crystal. Consequently, the composition of the element itself changes chemically, resulting in the development of color, due to the greater intensity of the pigment.

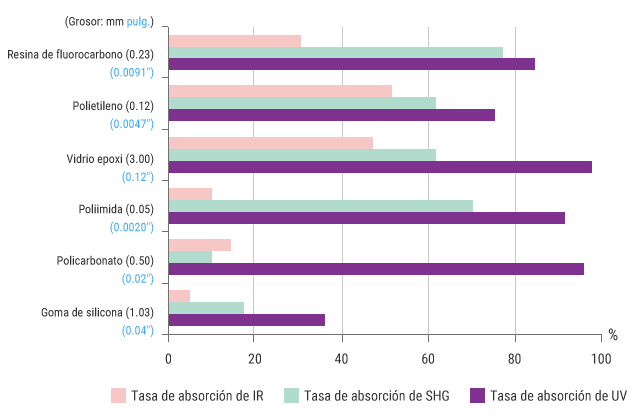

Plastic absorption rate

Variations in the material absorption rate per wavelength

The following graph shows the transmission ratio of a fundamental laser (1064 nm), a green laser (532 nm) and a UV laser (355 nm) for various plastic materials. For PVC, ABS and polystyrene, both fundamental and green lasers show a low transmission ratio and a high absorption ratio, which ensures a good marking. On the other hand, the transmission ratio for polyimide is approx. 30% with a green laser (532 nm), but more than 90% with a fundamental laser (1064 nm). The absorption ratio varies greatly depending on the wavelength.

Besides, please see the next blog for other information.