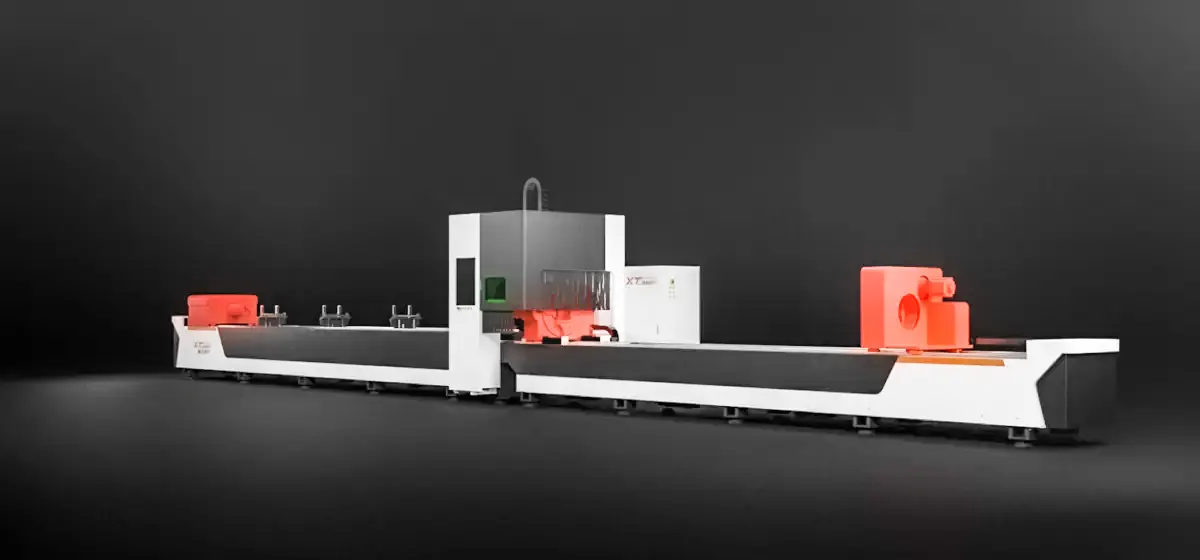

TP Series

Three Chucks Fiber Laser Pipe Cutting Machine

Optional Power: 1500W-6000W

Clamping Range: φ20-240mm

Standardization No Longer Uniform

Reduce Consumption

Equipped with appropriate tube nesting templates, the TP series laser pipe cutting machine achieves ultra-short remnants, reducing material waste and improving cost-effectiveness.

Expandable Options

XTlaser provides various expansion options, such as semi-automatic/automatic loading, to meet customers' efficiency needs for tube laser cutting.

Unrestricted Tube Shapes

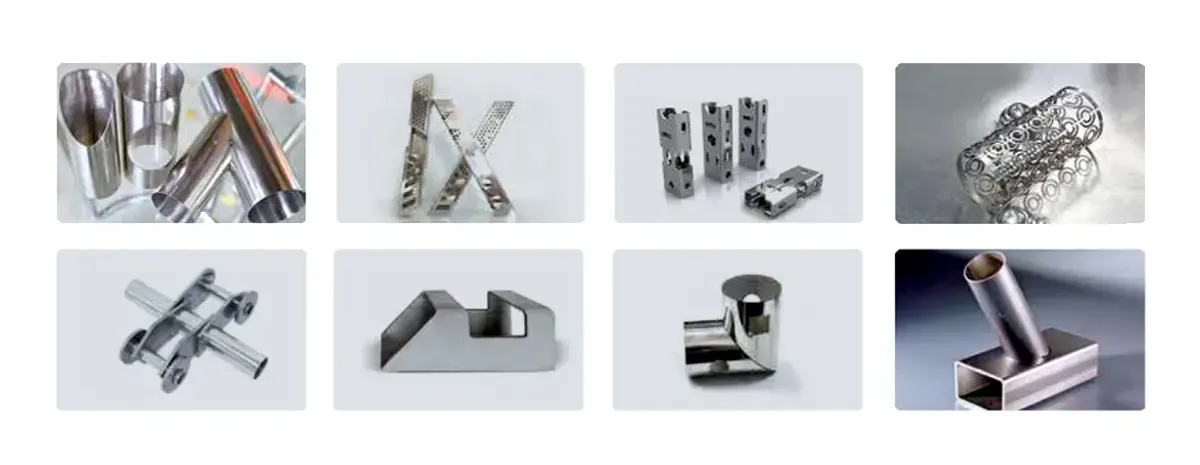

Whether round, square, or rectangular tubes, the TP series can handle them with ease, providing customers with more options for tube processing.

Features of the Three-Chuck Laser Tube Cutting Machine

Moveable Three-Chuck

Equipped with three movable chucks, it can easily clamp metal pipes with diameters ranging from 20mm to 240mm. Additionally, the chuck positions can be adjusted as needed to cut both ends of the metal pipe, maximizing material utilization.

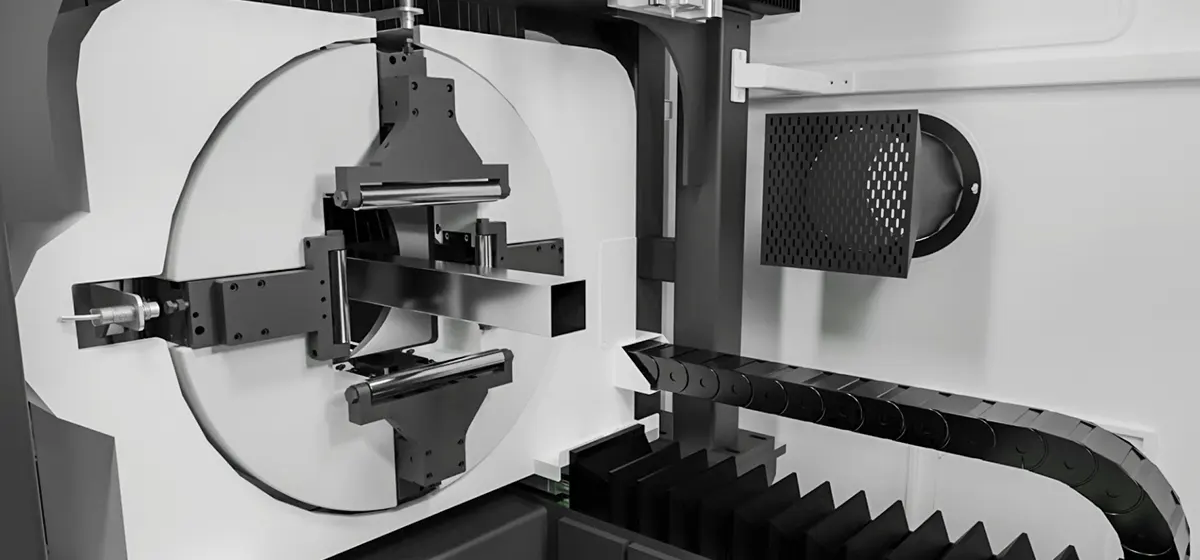

Pneumatic Large Chuck

The chuck clamps the workpiece and automatically positions the center and edges of the pipe. During the cutting process, the chuck remains clamped, ensuring stability and cutting accuracy.

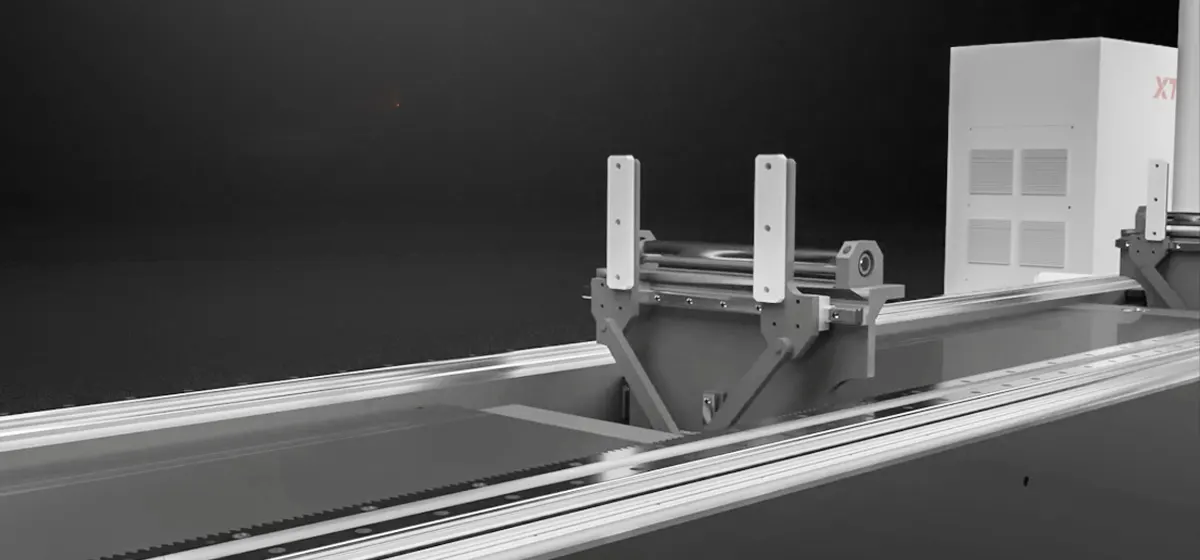

Servo Following Material Support Device

The CNC-controlled material support device can easily support various shapes of metal pipes, avoiding deformation during pipe processing. It is more flexible and precise than traditional supports.

Specifications

| Model | XT-TP230 |

| Tube Length(mm) | 6000mm / 9000mm |

| Laser Power(W) | 1500W-6000W |

| Maximum Chuck Speed | 80r/min |

| Maximum Acceleration | 1.5G |

| Position Accuracy | ±0.05mm |

| Tube Cross-Section Shape | Round/Square/Rectangular Tube |

| Processing Materials | Carbon steel pipes, stainless steel pipes, silicon steel pipes, aluminium alloy pipes and other metal pipes |

Application Fields

Architectural Decoration

High power laser cutting machines are widely used in cutting body parts, chassis components, and welding preparation in the automotive industry, improving production efficiency and automotive quality, and advancing automotive manufacturing technology.

Metal pipe processing

The high-precision cutting and processing of oil and gas pipelines, water supply pipelines, etc., cannot be separated from laser tube cutting machines. The cutting machine ensures the accuracy and quality of pipeline connections, improving the construction efficiency and reliability of pipeline processing.

Sports Equipment

In the field of sports equipment, fiber laser tube cutting machines are ubiquitous. They can be used to process frames, handrails, etc., for fitness equipment, ensuring component accuracy and precision, and improving the quality of sports equipment.

Laser Cutting Samples

If you need free sample services for metal pipes of various shapes and materials, please click the button below.

Contact us for professional technical support, online quotes, catalogs or demo videos.

- Email:manager@xtlaser.com

- WhatsApp: +8618753177006

- Wechat: xtlasermachine