100W-1000W

Pulse model laser

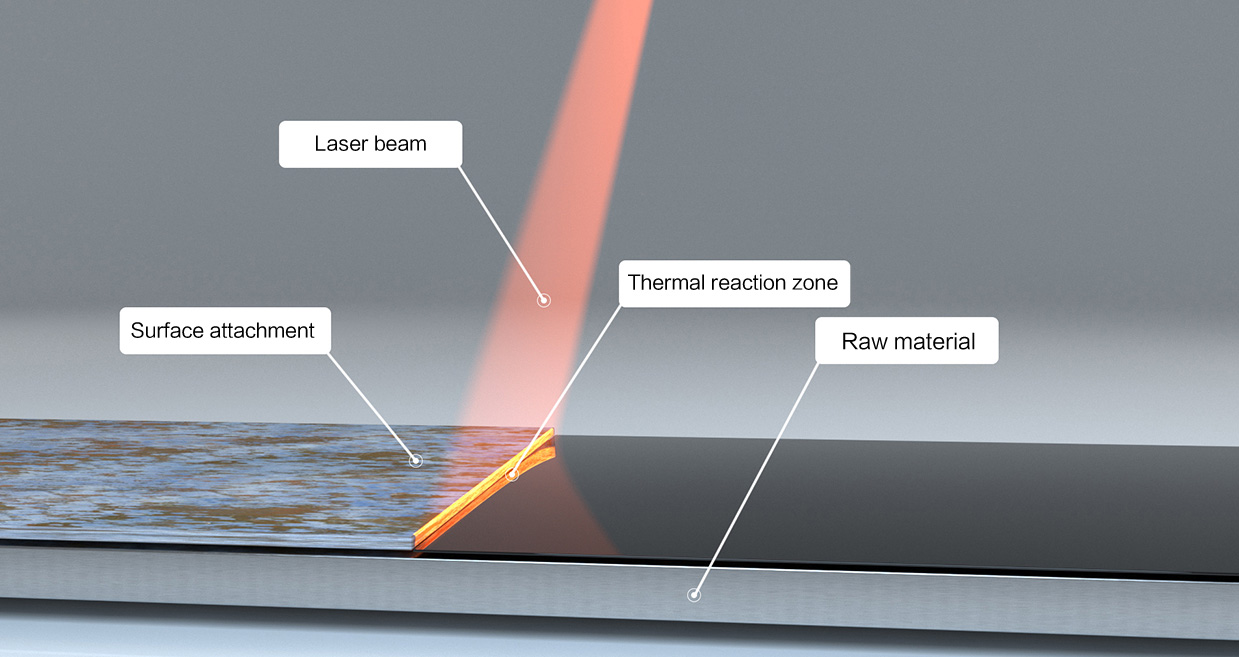

No Harm to Materials

Easy to Install and Control

No Harm to Materials

Easy to Install and Control

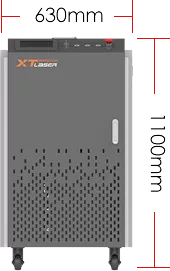

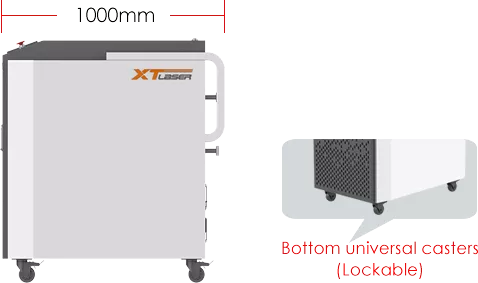

Machine is integrated and less floorspace occupation

10m(≥200w) optical fiber cable enables long-distance cleaning

Top push&pull handle and bottom universal wheels help useres to move machine easily

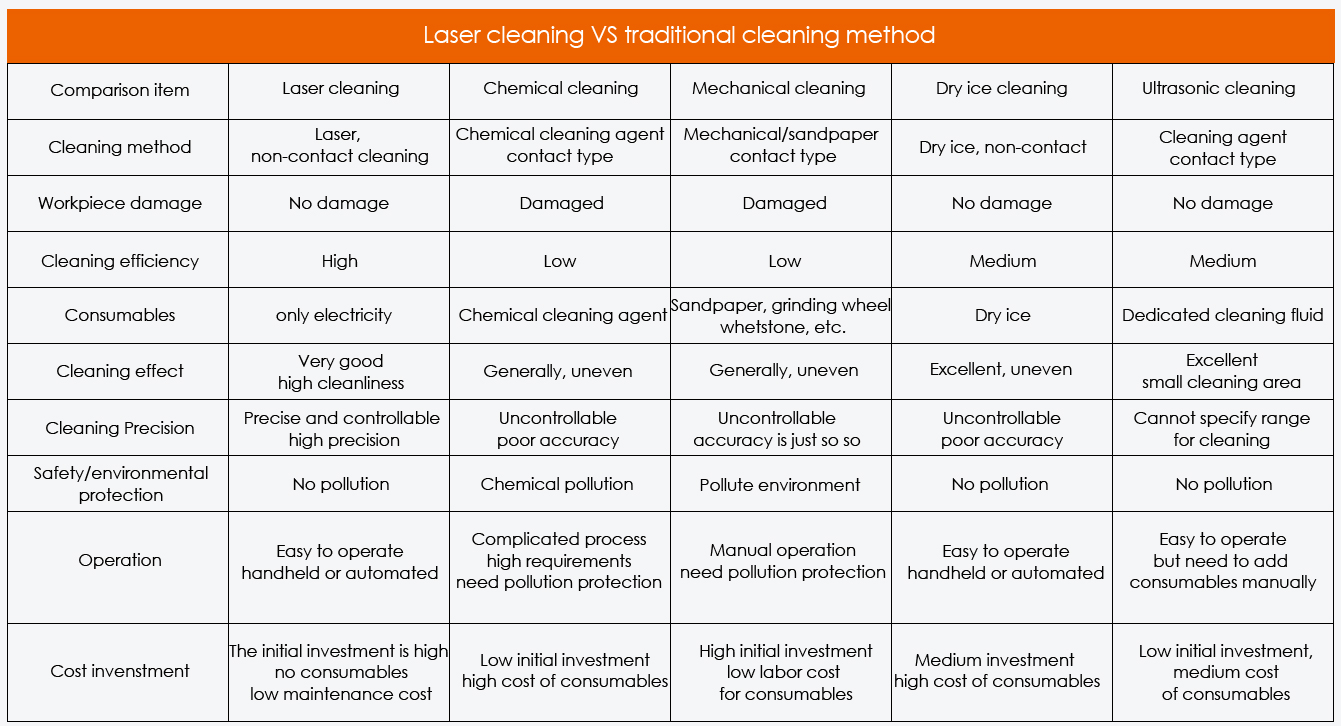

When compared with traditional cleaning tools, Fiber laser cleaning

machine has big advantages

Small size, light weight, convenient for manual use.

The front support frame can achieve precise cleaning and complete the cleaning work on the focal plane.

The operation is simple, just turn on the power, and can be handheld or used with a robot to achieve automatic cleaning.

The line width of the laser cleaning light and the speed

of the galvanometer swing can be adjusted by pressing the

button on the head of the handheld gun.

The laser cleaning gun head has high anti-vibration stability.

Good cleaning effect and high efficiency

Automated operation, stable cleaning

No chemical cleaning solution required, no consumables

Real-time monitoring of cleaning results

Able to achieve cleaning of specific locations and sizes

Low operating costs,laser cleaning system is stable

Little to no maintenance required

Host control system

Clear and concise interface, easy to operate

Parameters can be set by yourself to control the laser and galvanometer.

Cleaning various metal surfaces,

rust removal, rubber abrasive cleaning,

oil stains, dirt, welding surfaces, plating, coatings, etc.

Green energy saving, safe and low consumption

Can accurately position and clean,

Protects brittle material surfaces while effectively removing contaminant particles

No professional technical personnel required, can get started after simple training, which greatly reduces the difficulty of personnel recruitment.

Without damaging the material,

sensitive materials such as aluminum, carbon, stainless steel and carbon fiber reinforced polymer coating material, and tiny gaps all can be cleaned.

Contact us for professional technical support, online quotes, catalogs or demo videos.

- Email:manager@xtlaser.com

- WhatsApp: +8618753177006

- Wechat: xtlasermachine