Automatic Sheet Metal Bending Machine

- Flexible bending centers are capable of fully automated and fast production.

- The equipment is capable of using changing product requirements and can handle many different shapes and sizes of metal products at the same time.

- Whether small or large batches, they can be adapted to the company's processing needs and can be used for continuous production without the need for manual adjustments.

Automatic Sheet Metal Bending Machine Excellent Performance

Precision with Less Error

With high precision, the processed metal products have low error and high consistency. Effectively reduce the scrap rate and improve product quality.

High Efficiency

Non-professional skilled workers can learn to operate within 2-hour. Compared with the traditional bending machine, the production capacity is increased by more than 3 times.

Customizable

The bending size and thickness can be customized according to your sheet metal processing needs to meet the specific requirements of different products.

Automatic Sheet Metal Bending Machine Details

All-In-One Integrated Design

The integrated and integrated design of the operator’s console, electrical components, and monitor provides a small footprint, easy operation, and convenient maintenance.

It simplifies the installation and maintenance of the machine and reduces complex wiring and connections, thus improving the reliability and stability of the equipment.

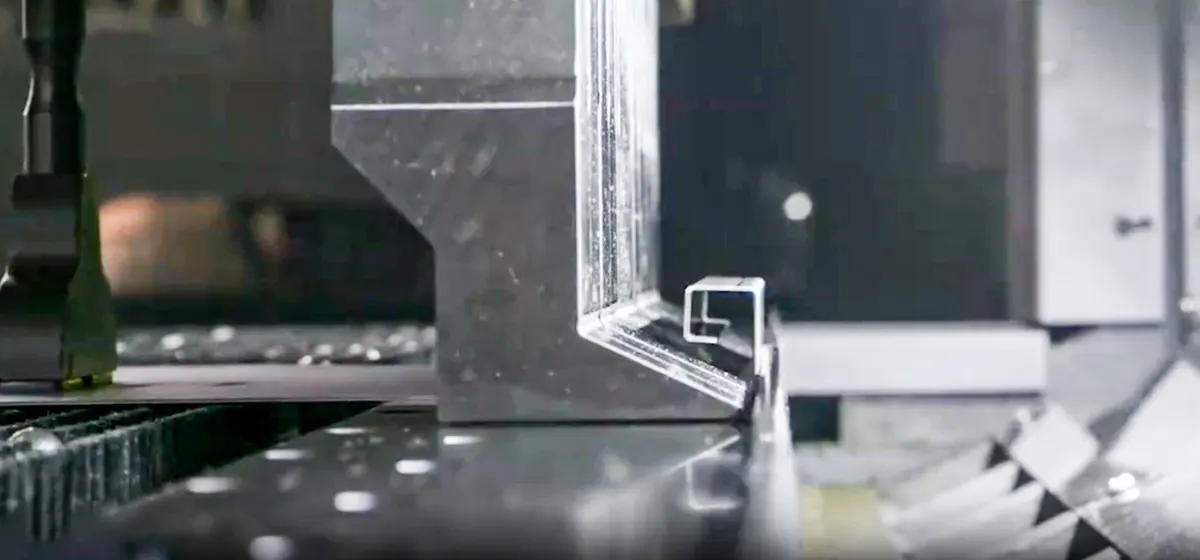

Can Bend Various Shapes

Without additional tooling costs, a set of universal cutters can easily achieve circular arcs, return shapes, closed shapes, and other types of shapes.

The machine can upward and downward bending, staggered bending, and eccentric bending to meet the needs of complex workpieces.

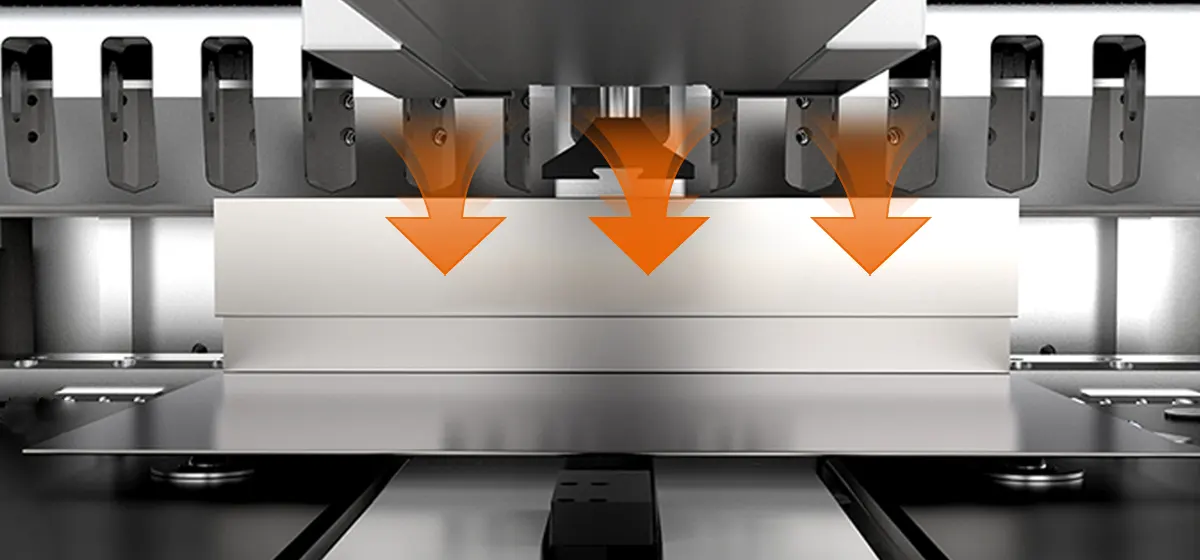

Fast Bending Speed

Workers only need to place the workpiece on the table, bending machine will automatically position and bend.

Whether it is a stainless steel plate, aluminum plate, or cold rolled sheet, each bending can be completed as soon as 0.2 seconds, the production speed is fast.

Specifications

Application Fields

Metal Cabinet Processing

Flexible bending centers are widely used in the mass production of various types of metal cabinets, such as filing cabinets, tool cabinets, electrical cabinets, distribution cabinets, etc., due to their high precision and efficiency, which ensures accurate cabinet dimensions.

Kitchenware Processing

In the field of kitchenware manufacturing, the flexible bending center can be used to process stainless steel cabinets, sinks, range hoods, stove top panels, etc. Its versatility can realize the bending of various complex shapes to meet the diversified needs of kitchenware design.

Metal Door Processing

Flexible bending centers are used in the manufacture of metal doors to accurately bend door frames, door panels, and other components to ensure a solid structure and precise dimensions of the door body, as well as to meet the needs of different door designs.

Sheet Metal Bending Samples

If you need free sample services for metal bending of various shapes and materials, please click the button below.

Contact us for professional technical support, online quotes, catalogs or demo videos.

- Email:manager@xtlaser.com

- WhatsApp: +8618753177006

- Wechat: xtlasermachine