4 Reasons That Effect Marking Uneven Of Laser Marking Machine-Anne

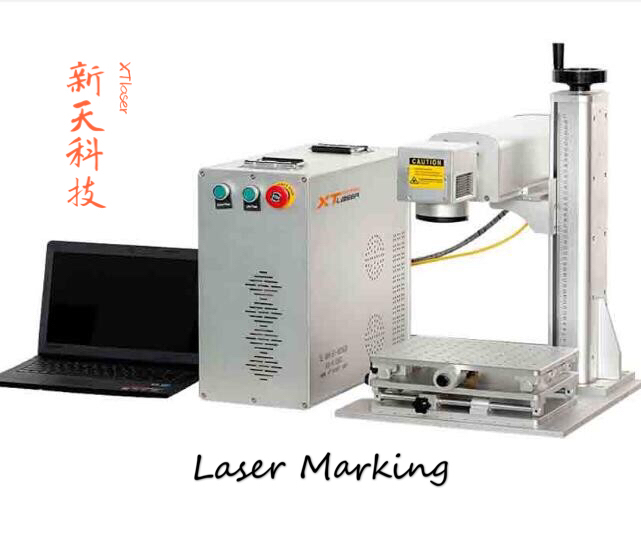

4 Reasons That Effect Marking Uneven Of Laser Marking Machine

In the marking process, sometimes the marking effect will be uneven.

Under these circumstances, fiber laser marking machine may has the following problems.

1.If Laser output spot is blocked.

Laser output head, fixed fixture and galvanometer are not adjusted,Part of the spot is blocked when the laser passes through the vibrating lens.This may also result in uneven results.

2.so Thermal lens phenomenon.

When the laser passes through the optical lens, it will cause the lens to generate heat and produce a slight deformation. This deformation causes the laser focus to rise and the focus to be shorter. There by changing the laser energy density on the material.

3.If The machine is not on a horizontal line.

Since the laser lens is not parallel to the processing table, the length of the laser beam passing through the field lens and reaching the workpiece is inconsistent. The energy of the laser falling on the workpiece will have inconsistent energy density.

4.so Caused by the marked material.

Marking materials are sensitive to the response of laser energy. Usually under the same material, the laser energy reaches a material damage threshold is certain.

When the thickness of the material coating is different, or some other physicochemical treatment processes are not uniform enough, it will also cause unevenness of the effect after laser marking.

Hope these information is help for you,if you have any questions of machine ,please feel free contact us.

Sales Manager:Anne Zhang

Mob.whatsapp:+8615098735595 Skype:amyzhang1321 Email:xintian121@xtlaser.com