Fiber laser cutting machine flame plasma cutting-Sara

Fiber laser cutting machine flame plasma cutting-Sara

First-Fiber laser cutting machine flame plasma cutting -flame

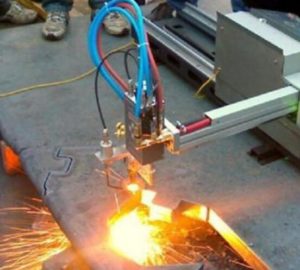

Flame cutting -fiber laser cutting is oldest hot cutting way. Tts cutting metal thickness from 1 mm to 1200mm. But when your cutting work is mainly low-carbon steel plate . like plate thickness below 20 mm. Better in other cutting methods. Because flame cutting heat affect area is much larger. Thermal deformation is relatively large.

In order to cut accurately and effectively with flame cutting. Operators need to have super opration technology during cutting process. To avoid the thermal deformation of the metal plate.

Second- Fiber laser cutting machine flame plasma cutting -plasma

plasma cutting and fiber laser cutting consumption is 6-7 times of fiber. While maintenance also cost a lot of energy and money. fiber laser cutting is free maintenance. Plasma subsequent costs are too high. Plasma has more hear effect during cutting procession . Using 5 years maybe not cheaper than optical fiber. but the benefits for you is much less than the fiber.

Third- Fiber laser cutting machine

Fiber laser cutting , is high precision and high efficiency. Fiber laser cutting has no limited to cutting pattern. It can cut any pattern on any metal material. The mechanical part of the laser cutting head don’t contact with the workpiece. There is no damage to material surface .So it can keep smooth incision . Keep less cutting heat affect zone.

The incision has no mechanical stress. Cutting sample no shearing burr. There is high processing precision, good repeatability.

Fiber laser cutting has high cutting speed. With automatic typesetting to save materials . fibe laser also has low processing costs. Fiber laser has NC programming. Fiber laser also can process any floor plan. Can be a large format of the whole plate cutting. There is no need to open mold. It is more economic and time-saving.

Fiber laser cutting will gradually improve or replace the traditional metal cutting process. Like waterjet cutting, flame cutting, and plasma cutting.

After read these cutting ways and features, details. which one cutting way is suitable for your work?