Power of Laser:

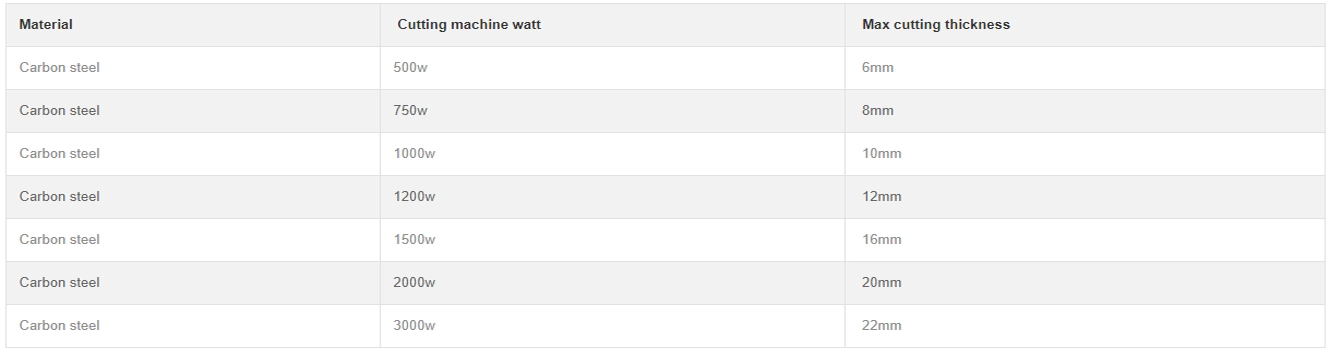

Also, a lower power laser beam is utilize when we want a greater cutting precision. On the other hand, thicker and more durable materials require a higher powered laser beam. For example, an 8mm metal sheet requires at least 1000 watts to cut effectively.

Pulse Frequency:

laser cutting Type of Gas:

Gas Pressure:

The pressure of the laser gas is another important factor to keep in mind. The gas pressure is influence he thickness of the material to cut. The thinner the material, the lower the gas pressure or there is a risk of damaging the material and the laser device itself.

Nozzles Size:

The cutting nozzles significantly influence the laser cutting process. For example, when we have to deal with low-pressure laser cutting, smaller nozzles are require. Conversely, when the material machining calls for a higher-pressure cut, then we need to use larger nozzles.

Nozzle Distance from Material Surface:

The distance of the nozzles from the cutting surface plays an important role in the quality of the final laser cut result. As a rule of thumb, the shorter the distance between the tip and the surface, the more precise and higher-quality cut we have.

Focus Lens Condition:

The focus lens needs to be clean and in perfect condition at all times. If there are pollution traces on the lens, then the laser cutting process is hindered and the results are of lower quality. Furthermore, a dirty focus lens is the main culprit for increased temperatures that may harm the laser device.

Hope the above can help you in your metal sheets cutting process, especially in CS Cutting. Any question about fiber laser cutting, welcome to contact us.

SEND US MAIL