At present, fiber laser cutting machines are mainly used in sheet metal processing, hardware products, kitchen utensils, machinery manufacturing, aerospace, auto parts manufacturing, communication equipment, steel structures and other related manufacturing and processing industries. Different industries, different products, and different processing requirements have different power requirements. Small fiber laser cutting machine is mainly used in hardware, kitchen and bathroom utensils and other industries. Medium power fiber laser cutting machine is mainly used in advertising, sheet metal processing, fitness equipment, chassis and other industries. High-power fiber laser cutting machines are mainly used in aerospace, rail transit, auto parts manufacturing, communication equipment, high-end mechanical equipment manufacturing and other industries.

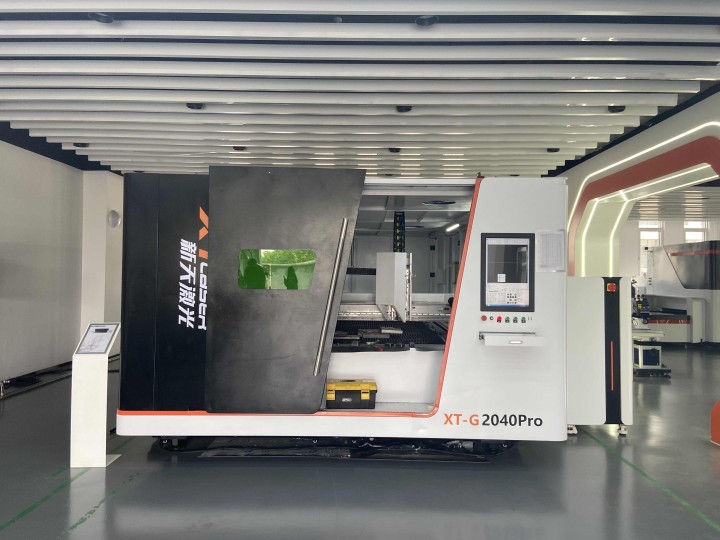

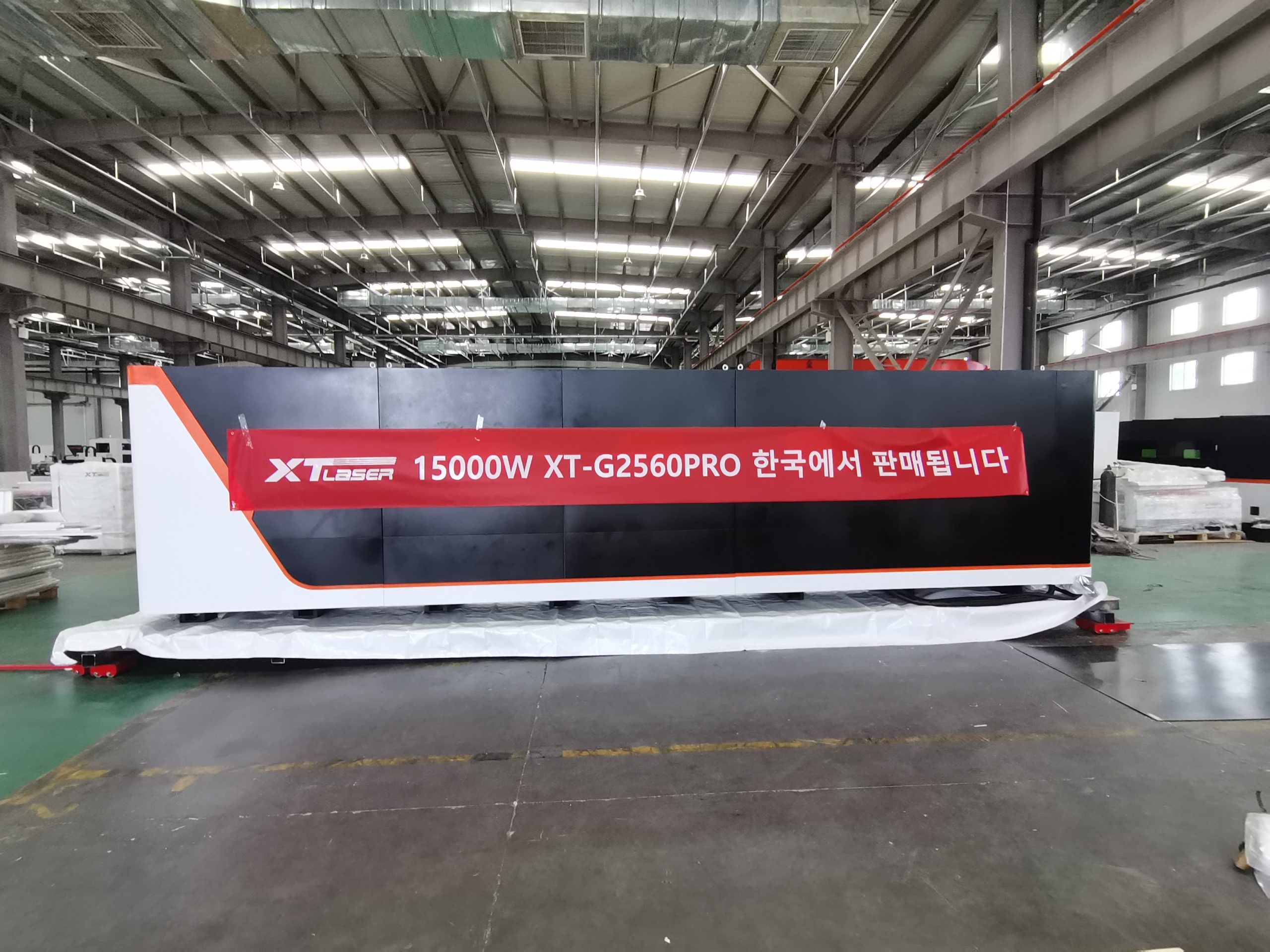

In general, the choice of how much power fiber laser cutting machine depends on the cutting needs of customers. After the above comparison, everyone has an in-depth understanding of the 12kW and 20kW laser cutting machine products. In fact, no matter how much power, the most suitable one is the best. When purchasing a fiber laser cutting machine, customers can choose from various aspects such as processing detail requirements, thickness, speed, and price. At the same time, match the corresponding power size according to the material to be processed, and don’t forget to check whether the price meets your budget. If you want to learn more about 10kW+ fiber laser cutting machine, please contact XT LASER.

Eveline Liu

WhatsApp/ Wechat:+86 13046007257

Email: xintian131@xtlaser.com