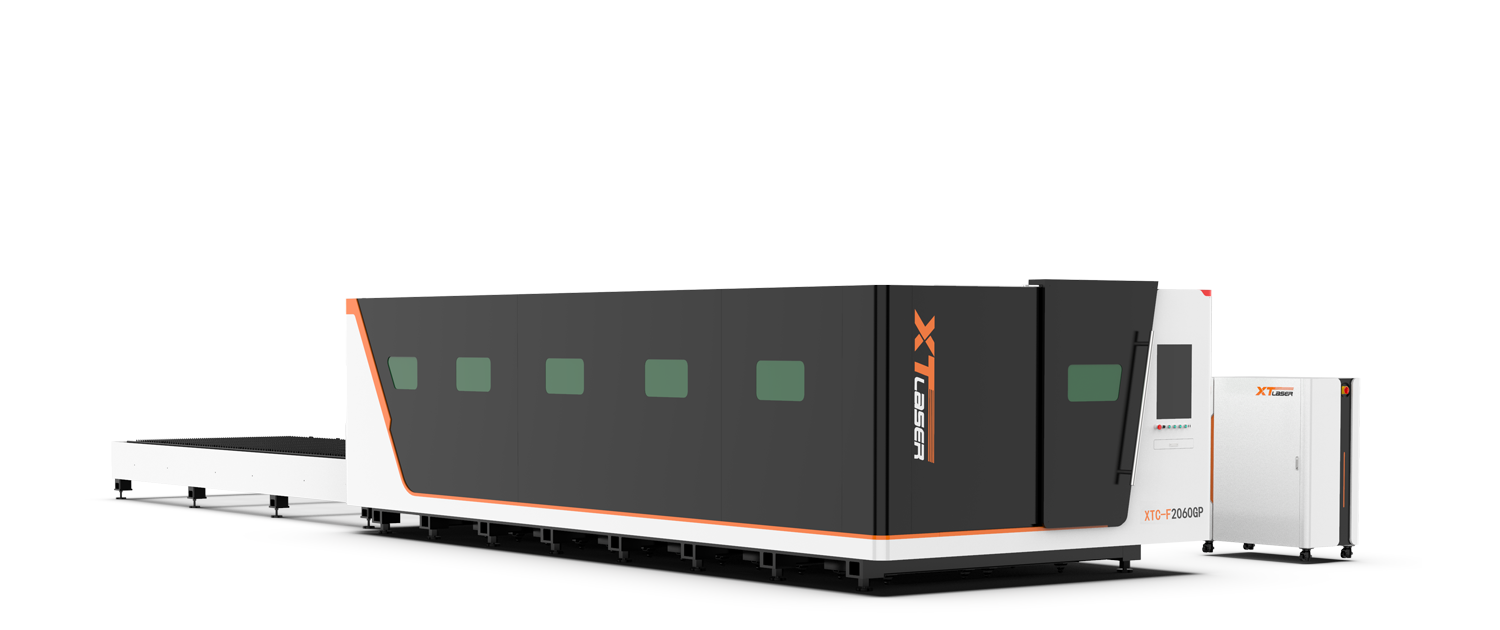

12kw Fiber laser cutter–Oriole

12kw fiber laser cutter

Firstly, changes to the sheet metal processing industry

The first is to increase the thickness range of different plate processing. In the period of CO2 laser cutting, the maximum power of the laser is under 6000w. The thickness of early fiber laser cutting plates is carbon steel within 20mm and stainless steel within 12mm. Thicker materials are still Traditional processing techniques such as fine plasma, wire cutting or waterjet cutting.

Ten thousand watt fiber laser cutting is the first revolutionary change in the field of sheet metal processing. This is the continuous improvement of the thickness of different materials: aluminum alloy plates can reach 40mm, and stainless steel plates can reach 50mm. With 12kw and 15kw fiber laser cutting machines With the continuous introduction of the, the thickness limit of material cutting will continue to be broken, and the processing price of thick plates will be further reduced, which will trigger more laser applications in the latter half of the field, such as shipbuilding, nuclear power, and national defense. As a result, a virtuous circle is formed, and as a result, a field of use for promoting laser cutting is further expanded.

Secondly, Economic benefit

In addition to the increase in cutting thickness, the cutting efficiency of 10,000-watt laser cutting in the field of medium and thin plates is also improved by multiple levels. When cutting stainless steel plates with a thickness of 3-10mm, the cutting speed of the 10kw laser cutting machine is more than twice that of 6kw. At the same time, the 10kw laser cutting machine can reach 18-20mm/s in the application of carbon steel cutting. Fast double-sided cutting is twice the speed of ordinary standard cutting. It can also cut carbon steel within 12mm with compressed air or nitrogen. And the cutting efficiency is six to seven times the speed of oxygen cutting carbon steel.

The efficiency of high-power laser cutting of thin plates has greatly surpassed people’s past imagination. This is the main reason why high-power laser cutting machines are popular in the sheet metal market. From the perspective of economic benefits, the price of a 10kw laser cutting machine tool is less than 40% higher than that of a 6kw machine tool, but the output efficiency per unit time is more than twice that of a 6kw machine, and it saves labor and space. To the favor of laser processing business owners.

Any interests please feel free to contact us.

Oriole

Whatsapp/Wechat: 008613731273956