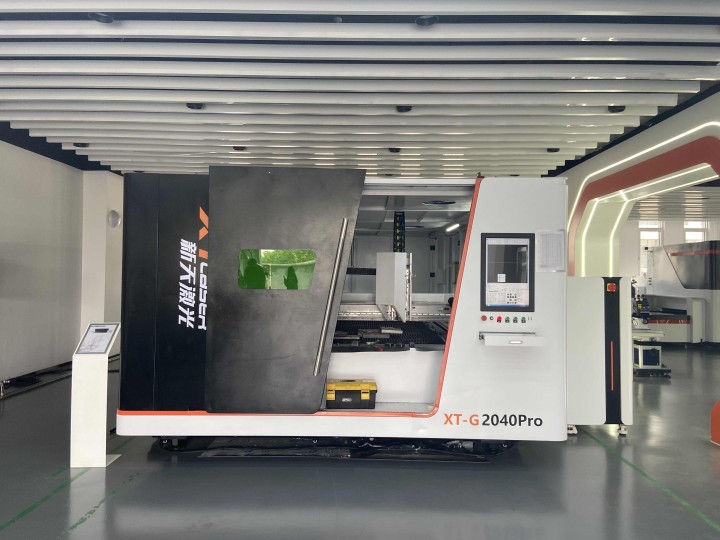

High Power Laser Cutting Machine from XTLASER-Eliza

High Power Laser Cutting Machine from XTLASER

High power laser cutting machine. With the development of laser technology. High-power laser cutting machines can use air cutting when cutting carbon steel materials of more than 10mm. The cutting effect and speed are much better than those with low and medium power limit power cutting. Not only has the gas cost in the process reduced, and the speed is also several times higher than before. It is becoming more and more popular among metal processing industry.

The super high-power fiber laser cutting machine technology has obvious advantages when cutting metal materials of different thicknesses. How to correctly use the super-power fiber laser cutting machine to achieve the ideal cutting effect requires mastering its processing technical parameters and operating procedures. Especially in the cutting process of metal laser cutting machine, you must choose the appropriate cutting speed, otherwise it may cause several bad cutting results. The main manifestations are as follows:

What is the effect of the cutting speed of the high-power fiber cutter?

1. When the laser cutting speed is too fast, it will cause the following undesirable results:

① The phenomenon of inability to cut and random sparks;

②The cutting surface has oblique stripes, and melting stains are generated in the lower half;

③The whole section is thicker, and there is no melting stain;

2. When the laser cutting speed is too slow, it will cause:

①The cutting surface is rough, causing over-melting.

②The slit becomes wider and melts at the sharp corners.

③Affect the efficiency of cutting.

Therefore, in order to make the ultra-high-power fiber laser cutting machine better perform its cutting function, you can judge whether the feed speed is appropriate from the cutting spark of the laser equipment:

1. If the sparks spread from top to bottom, it indicates that the cutting speed is appropriate;

2. If the spark tilts backward, it indicates that the feed speed is too fast;

3. If the sparks appear to be non-spread and less, and condense together, it indicates that the speed is too slow.

So, with a good and steady laser cutting machine, and on time online afterserivce is also important to ensure the use of laser cutting machine.

Any questions, just feel free to contact

Eliza Liu

Whatsapp: 008613173025103

Email: lasermachine01@xtlaser.com