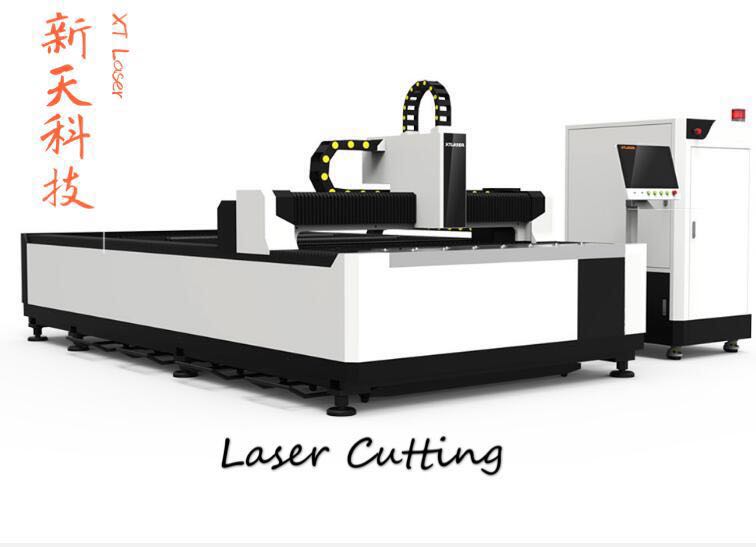

Presentación de la máquina láser de fibraóptica

Fiber laser has become a hot topic in laser physics research in recent years. It generally considere to a new generation of products.That may replace solid-state lasers and, in an all-round way. Fiber laser is a kind of laser using rare earth doped glass fiber as gain medium. Fiber laser can develope on the basis of fiber amplifier.

It is easy to form high power density.However in the fiber under the action of pumping light.Resulting in the laser energy level “particle number reversal” of the laser working substance. When the positive feedback loop (forming a resonator) is properly added.The laser oscillation output can be formed. Fiber laser marking machine is to use laser beams to mark the surface of various substances permanently.

The effect of marking is to expose deep substances through evaporation of surface substances.Or to “engrave” traces by physical changes of surface substances caused by light energy.Or to burn off some substances by light energy, showing the patterns, words.And barcodes and other graphics that need to be etched.

Presentación de ventajas

The advantages of miniaturization and intensification brought about by the low cost of glass fiber manufacturing. Mature technology and the availability of glass fiber.

Glass fibers do not need the strict phase matching of the incident pumping light as crystals. Which is due to the non-uniform broadening of the absorption band caus by Stark splitting of the glass matrix.

Glass material has very low volume-area ratio, fast heat dissipation and low loss.So it has high up-conversion efficiency and low laser threshold.

The output laser has many wavelengths.This is due to the rich energy levels of rare earth ions and the variety of rare earth ions.

Tunability: Because of the wide energy level of rare earth ions and the wide fluorescence spectrum of glass fibers.https://www.xtlaser.com/

Tendencias futuras

Because there is no optical lens in the resonator of the fiber laser, it has the advantages of no adjustment, and, no maintenance and high stability, which is incomparable with traditional lasers.

Fiber optic derivation makes the laser easily competent for all kinds of multi-dimensional arbitrary space processing applications, and makes the mechanical system design very simple.

Competent for harsh working environment, with high tolerance for dust, shock, humidity and temperature.

There is no need for thermoelectric refrigeration and water cooling, just simple air cooling.

High electro-optic efficiency: The comprehensive electro-optic efficiency is up to 20%.And, can greatly save power consumption and operation cost. High power, and, commercial fiber laser is 6 kW.