What are the specific requirements for the configuration of the laser cutting machine-Huda

What are the specific requirements for the configuration of the laser cutting machine

What are the specific requirements for the configuration of the laser cutting machine

Today, I will follow the editor to take a look at some different knowledge of laser cutting machine,

so that everyone has more understanding of laser cutting machine,

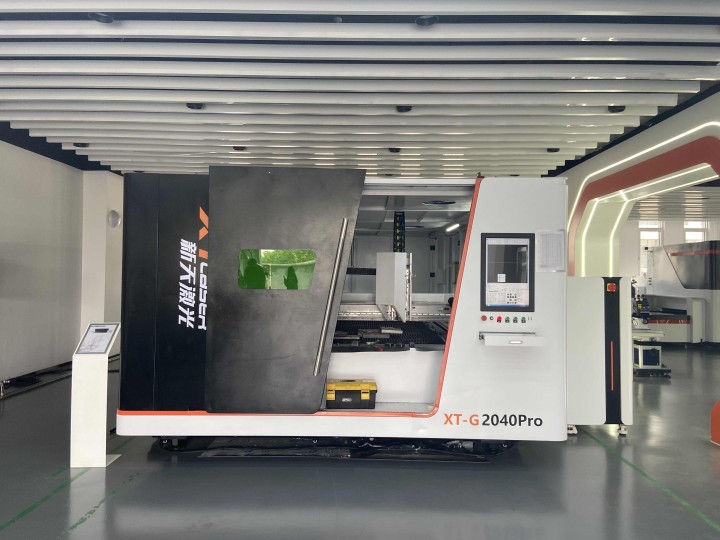

the following is XTLASER finishing Some specific requirements for the configuration of the laser cutting machine:

The processing and application of laser cutting machines have advantages in processing large-thickness steel plates.

How to achieve The key to such an amazing cutting thickness lies in the configuration and combination of cutting gas.

Laser cutting machine processing involves the mixing of different types of gases.

In order to improve cutting quality and efficiency, similar cutting gas source combinations are also different in relate parameter settings.

At present, the domestic mainstream laser cutting machine equipment adopts parameter preset mode, which is in the early stage of cutting processing.

The personnel input the relevant cutting parameters to operate, including the preheating time, cutting speed, cutting torch height and other parameters are really suitable for the cutting of this material?

The following editor would like to talk about our views on this issue.

The key to mastering the flame of the torch is the gas source. Most of the oxygen on site is supply by the pipeline.

The purity and pressure of the oxygen can generally meet the requirements for use.

However, the gas is mostly supply by bottled gas. In the flow scale, the use time is about 2 hours.

In this way, the gas source must be replace in the middle. This will cause large gas pressure fluctuations, which will directly affect the gas flow and cause abnormal cutting.

The bottled gas pressure at the beginning and end of each bottle of gas use

With large fluctuations, warm water heating is a good way to ensure the stability of the air source.

In order to ensure the cutting quality and effect, the laser cutting machine generally has qualitative and quantitative requirements for the cutting gas source,

including the purity, pressure and ratio of the cutting gas source, in order to ensure the cutting quality.