Série HR

Machine découpe laser pour métaux à faisceau en H

Taille traitement : 150 × 75 mm - 1 250 × 650 mm

Plage traitement longueur : 2500 mm-12500 mm

La coupe en biseau, le chargement et le déchargement automatiques ainsi que la collecte automatique des déchets peuvent être réalisés

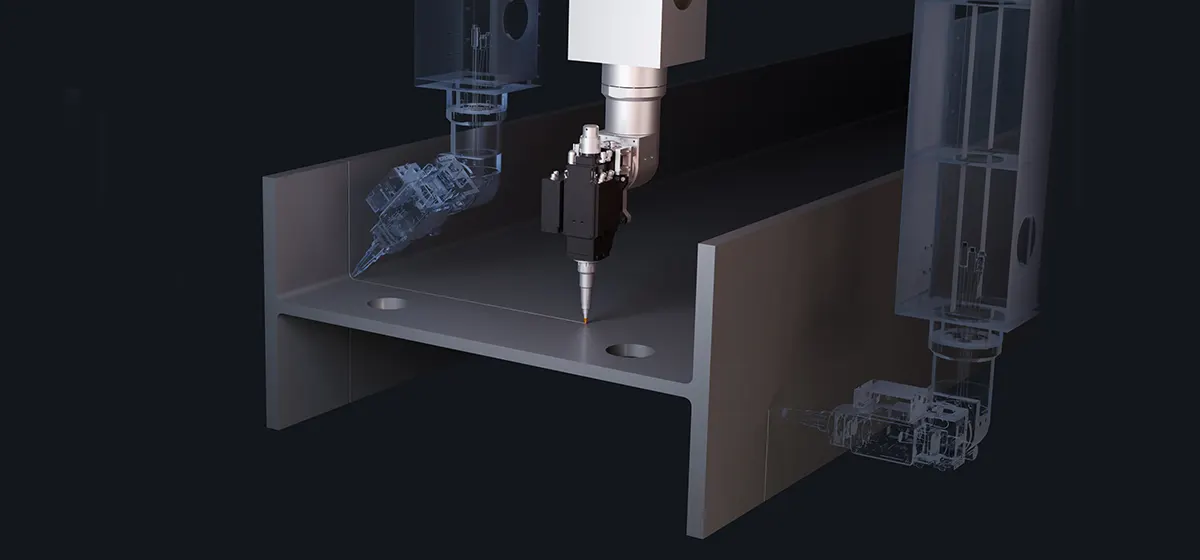

Détails la machine découpe laser en acier profilé en H

- Haute efficacité : la tête de coupe pivotante à axe AB est spécialement conçue pour les géométries complexes des poutres en H, permettant une coupe sous n'importe quel angle sans traitement secondaire, améliorant considérablement l'efficacité de la coupe.

- Intelligent : la tête de coupe est équipée de capteurs intelligents qui surveillent le processus de coupe en temps réel, ajustant automatiquement les paramètres de coupe pour garantir une qualité de coupe stable et fiable.

- Flexible : la tête de coupe peut ajuster de manière flexible l'angle et la position de coupe pour s'adapter aux besoins de coupe de différentes spécifications de poutres en H, répondant à diverses tâches de traitement.

- Précis : entraîné par des servomoteurs de haute précision, le positionnement de la tête de coupe est précis et les bords de coupe sont lisses et sans bavures, répondant aux exigences de traitement de haute précision.

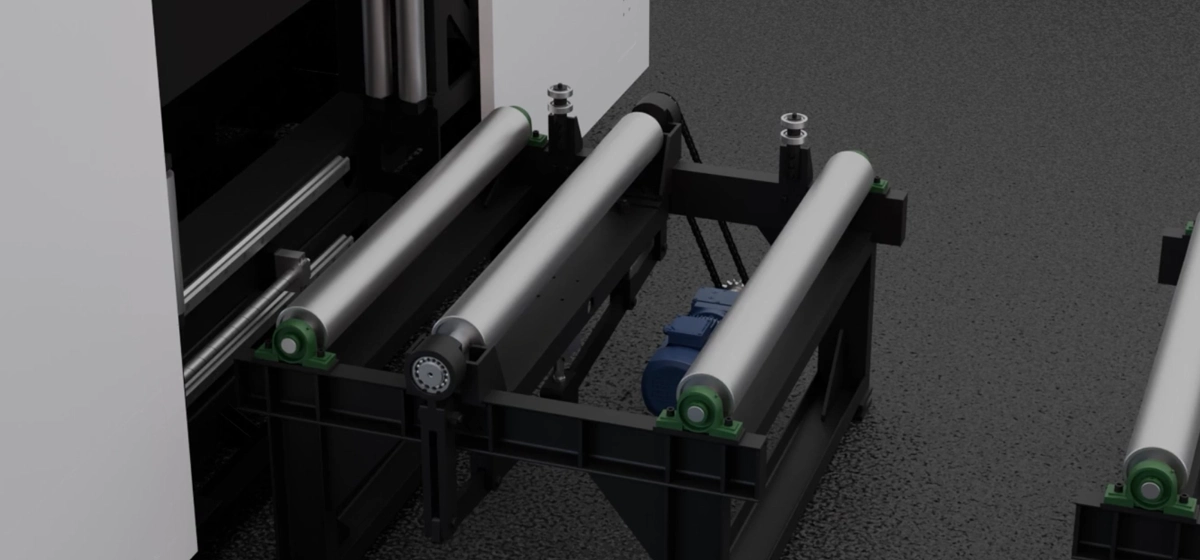

- Griffes d'alimentation : Fabriquées en acier allié à haute résistance, les griffes ont une forte force de serrage et une alimentation stable, assurant la continuité du processus de coupe.

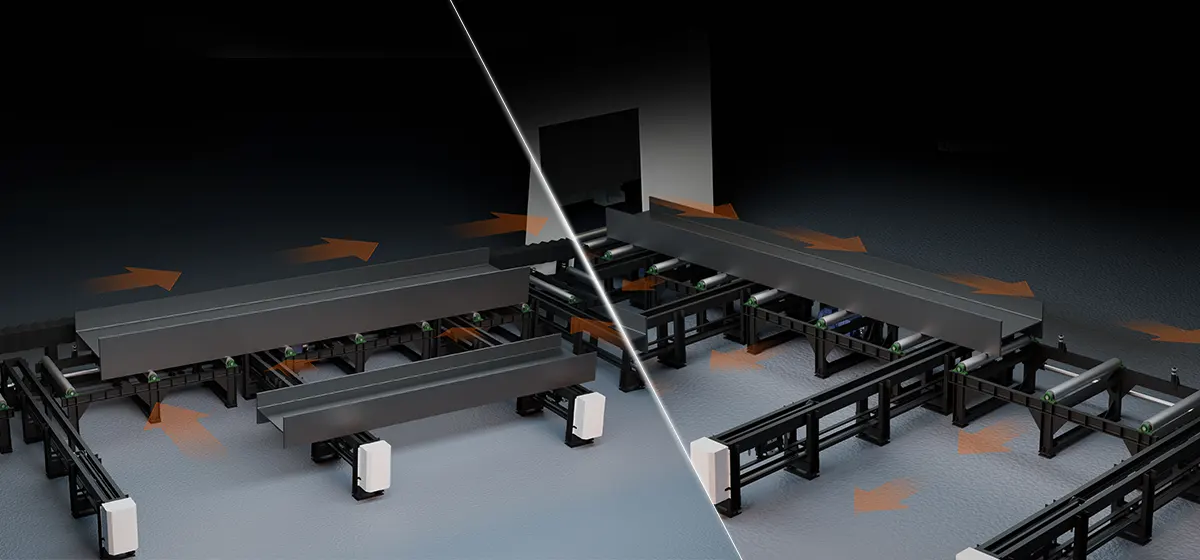

- Rack d'alimentation segmenté : peut être librement combiné en fonction de la longueur de la poutre en H, réalisant une alimentation en matériaux longs et courts, améliorant l'efficacité de l'alimentation et réduisant les opérations manuelles.

- Capteurs haute précision : surveillez la position de la poutre en H en temps réel, identifiez automatiquement les écarts et assurez la précision de la coupe.

- Algorithme intelligent : ajuste automatiquement le chemin de coupe en fonction de l'écart, permettant une coupe précise.

- Conception segmentée : combinez librement la taille de la table de chargement et de déchargement en fonction des besoins de traitement, en vous adaptant au traitement de poutres en H de différentes longueurs.

- Chariot élévateur : Soulève facilement les poutres en H, réalisant un chargement et un déchargement automatisés et réduisant l'intensité du travail.

- Dispositif d'entraînement de déchargement : entraîne automatiquement le déchargement des poutres en H coupées, améliorant ainsi l'efficacité de la production.

Champs d'application

Construction structures en acier

XT LASER H-beam laser cutting machines can achieve high-precision and high-efficiency H-beam cutting, meeting the strict requirements of steel structure buildings for component processing accuracy and efficiency. They are widely used in the construction of various steel structure buildings such as factories, bridges, and stadiums.

Fabrication de machines

H-beams are often used in machinery manufacturing to manufacture load-bearing structural parts such as frames and brackets. XT LASER H-beam laser cutting machines can achieve complex shape cutting and groove processing, meeting the requirements of machinery manufacturing for component processing accuracy.

Construction navale

H-beams are important structural materials in shipbuilding. XT LASER H-beam laser cutting machines can achieve cutting and groove processing of large-size H-beams, meeting the requirements of shipbuilding for large component processing, and improving shipbuilding efficiency and quality.

Échantillons découpe laser

Request a sample now and experience the outstanding performance of the XT LASER H-beam laser cutting machine for yourself!

Contactez-nous pour une assistance technique professionnelle, des devis en ligne, des catalogues ou des vidéos de démonstration.

- E-mail : manager@xtlaser.com

- WhatsApp : +8618753177006

- Wechat : xtlasermachine