Laser Welding operation Precautions-Serena

Laser Welding operation Precautions

Some laser welding operation precautions as following:

1.The first laser welding operation precautions,Read the instruction manual carefully. And operate the laser welding machine strictly in accordance with the operating procedures.Ensure the safety of equipment and personnel.

2.Check whether all parts of the welding machine are working properly.

Before welding, check whether all parts of the laser welding machine are working properly. After the operation, check the welding machine and the work site to eliminate hidden dangers. And ensure safety and accident-free.

3.Avoid fire caused by laser irradiation

Direct irradiation or strong reflection of the laser beam can cause combustible materials to burn and cause fire. In addition, there are thousands to tens of thousands of volts in the laser.Electric shock will injure it. Therefore, only trained staff are allowed to operate the laser welding machine. The optical path system of the laser must be fully enclosed with metal to prevent direct exposure, and the workbench for laser welding should also be shielded to prevent radiation.

And more

4.Avoid laser damage to eyes

The laser power density adopted by the laser welding machine is very high, and the beam is very thin.It can easily cause damage to human eyes and skin. Therefore, We should protect the eyes during laser welding operations. On-site operators must wear special laser protective glasses.

5. Avoid laser burns on the skin

Direct laser irradiation on the skin can cause burns to the skin, and long-term effects of diffuse reflection can also cause the operator’s skin to age, inflammation and skin cancer. On-site operators need to wear work clothes to reduce the influence of diffuse reflection.

6.The circulating water in the laser welding machine must be clean. Otherwise,it will affect the output of the laser. The user can determine the replacement cycle of cooling water. According to the startup time, water quality and other conditions. Generally speaking, the water replacement cycle in summer is shorter than that in winter.

7.The housing of the laser welding machine needs to connecte with a safety ground. During work, do not look at the laser beam with your eyes, and do not let your body (such as hands) touch the laser beam to avoid injury.

8.Keep the environment and laser welding machine clean, and check whether the laser rod and optical components are good.

9.If you need to overhaul the laser welding machine, you must cut off the power and make sure that the charge on the energy storage capacitor has been discharged before proceeding to avoid electric shock accidents. If abnormal phenomena occur during operation, cut off electricity (press <emergency stop> and air switch) to check.

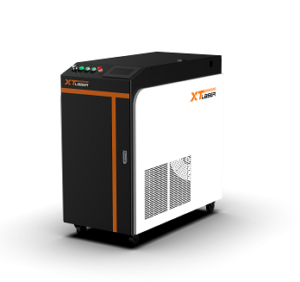

IF you have any question anout fiber laser welding machine ,please contact XT laser.