How to improve the efficiency of metal laser cutting machine?-Serena

How to improve the efficiency of metal laser cutting machine?

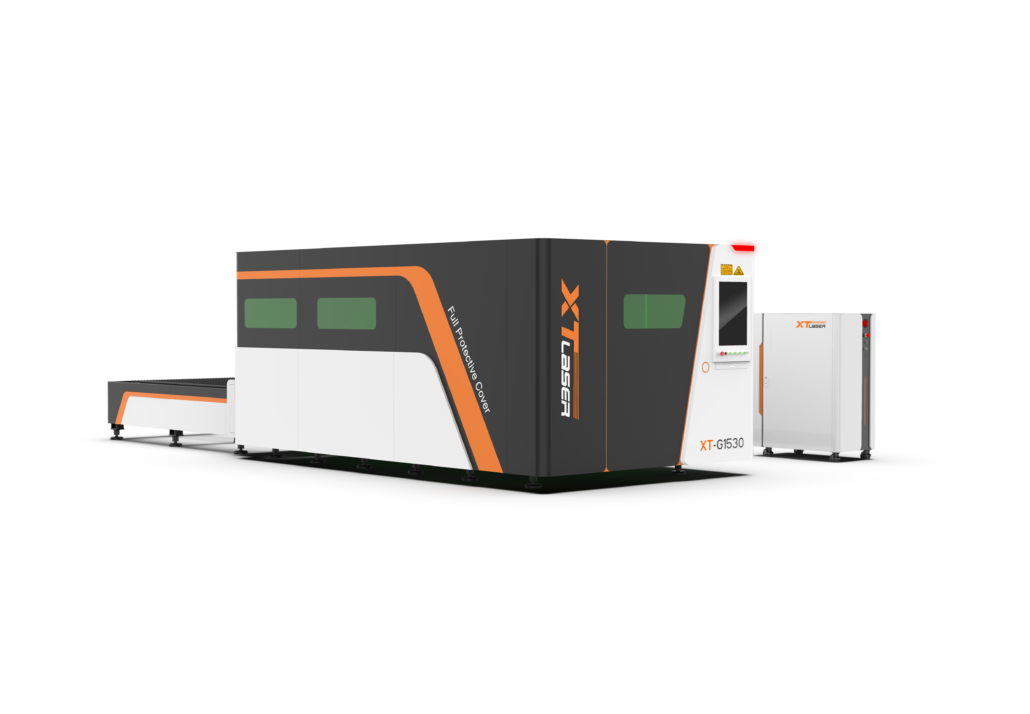

Metal laser cutting machine is becoming a common equipment in sheet metal processing now. Compared with traditional cutting machines. It has the characteristics of faster, more accurate and more stable. Although it has those advantages over CNC punching machine. How to give full play to its advantages is a question we have been studying.

Here are some notes:

1.Regular maintenance machine bed

The machine bed is a large part to ensure the stability of the metal cutting laser machine. The running speed of the machine mainly depends on the cooperation of the motor, the reducer and the guide rail rack. Therefore, if you want to improve efficiency, the maintenance of these components is indispensable.

2.Regular replacement of optical lenses

The laser beam is emitted by the laser device and then focused by the cutting head, achieving the cutting effect. There are many optical lenses in the cutting head. The laser beam expands and focuses through optical lenses. Because the working environment of the metal laser cutting machine is very harsh, the optical lens will pollute the lens with dust after a long time of work. At this time, the transmittance of the laser will be greatly reduced, and the cutting efficiency will decrease.Therefore, the optical lenses also need regular maintenance and replacement.

3.Set cutting parameters reasonably

During using machine, we need to cut patterns with different shapes. So the operators need to modify the program parameters of the laser metal cutting machine. Since operators need set the applicable cutting parameters according to the different materials and shapes, it is necessary for the them to be familiar with what parameters and procedures are suitable for different materials. The higher the fit between the laser cutting mode, the better the cutting quality.

4.Upgrade laser device

Some customers told us that when cutting thick plates, the cutting efficiency is not enough.The most likely reason is that the laser power is too low. Therefore, if you want better cutting effect, you most likely to increase the laser power. That is, upgrading the laser power is the most efficient method.

In the process of daily work, the operator must learn to record the small problems that often occur in the metal laser cutting machine. Any equipment has a service life. Only diligent maintenance, can your machine have stable performance.