Exhibition Preview! The XT laser galvanometer welding machine is about to shine!

Exhibition Preview! The XT laser galvanometer welding machine is about to shine!

September 20-24

The 2023 World Manufacturing Conference, which attracted widespread attention

To be held at the Binhu International Convention and Exhibition Center in Hefei, Anhui Province

Grand Opening

New products at XT booth

Laser galvanometer welding machine

Coming soon

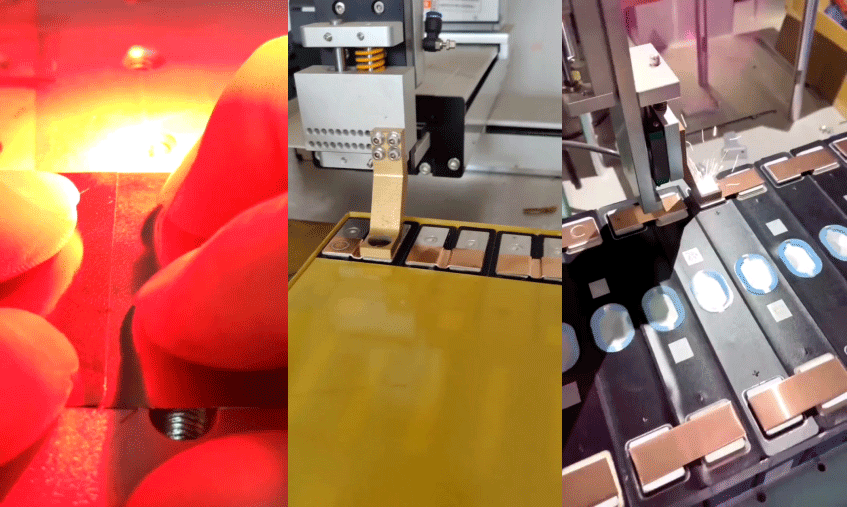

Let’s take a look at the real face first

Batteries are ubiquitous in our daily lives

New energy vehicle batteries, mobile phone batteries, electric vehicle batteries

They are always convenient for our lives

In the battery industry chain

Laser welding is mainly applied in the battery production process

As a high-precision welding method

Due to its extremely flexible, precise, and efficient characteristics

Meet the performance and efficiency requirements during battery production

Thus becoming the preferred choice in the battery manufacturing process

High power welding galvanometer kit

High power | High precision | High linearity | Ultra low temperature drift

Innovation leads and empowers production

The new generation motor, new generation drive scheme, and efficient water-cooled sealing structure designed specifically for ultra-high power laser welding applications ensure stable and reliable production and processing.

Adhere to quality and strive for excellence with craftsmanship

A complete product quality control system, all galvanometers undergo 360 hours of ultra long aging testing before leaving the factory, ensuring consistent quality.

Strong performance and exceptional experience

We have adopted advanced PID improved closed-loop algorithm, unique linear compensation technology, parallelogram correction technology, precise temperature drift automatic compensation technology, multi-level anti-interference high reliability protection array circuit and other technologies, with excellent performance and processing speed.

More efficient power and full capacity

Adopting specially customized high-power optical lens components, combined with efficient water cooling structure and multi-level temperature protection function, it can withstand up to 6000W of laser power.

Accurate control in one step

Fast scanning | Accurate positioning | Visual adjustment | Easy operation

Multi axis control for precise positioning

Multi axis linkage control of the machine, with multiple workstation settings, spot welding, I/O control, teaching welding, and other functions. The size of the welding spot can be edited to achieve fine and beautiful welding seams.

Diversified processing to meet the needs of universities

There are five motion modes: continuous inching, incremental inching, return to origin, handwheel, and automatic, providing a more user-friendly human-machine interaction experience and easy to operate.

Safety protection in advance

Equipped with an abnormal monitoring and alarm system, it can detect abnormal situations such as galvanometer power supply, motor operation, and drive board in real-time. It can actively cut off the laser circuit, handle abnormalities in a timely manner, and ensure safe production.

At present, the process of using laser welding in the production of power batteries mainly includes:

① Middle process: pairing pre welding of pole ears, spot welding of pole strips, pre welding of battery cells, welding of shell sealing, sealing welding of liquid injection ports, etc

② Post process: including welding of connecting pieces, welding of explosion-proof valves, etc.

It is widely used in industries such as notebooks, electrode pads, microelectronic components, precision parts, intelligent terminal product components, and laser welding between various metal materials such as carbon steel, stainless steel, copper, aluminum, zinc plating, etc.

XT laser galvanometer welding machine

Using laser beams as energy source

High welding speed and automation level

Good stability and stronger connection

Improve efficiency, simplify processes, and save labor costs

Solve a series of processing difficulties for battery production

For more product information, industry solutions, etc

Welcome everyone to visit and exchange ideas on site

Exhibition booths D14 and D15 of Hall 3, stay tuned!