Nowadays,handheld welding machines are more and more popular in manufacturing.So how to maintain the Welding Machine in our daily use?

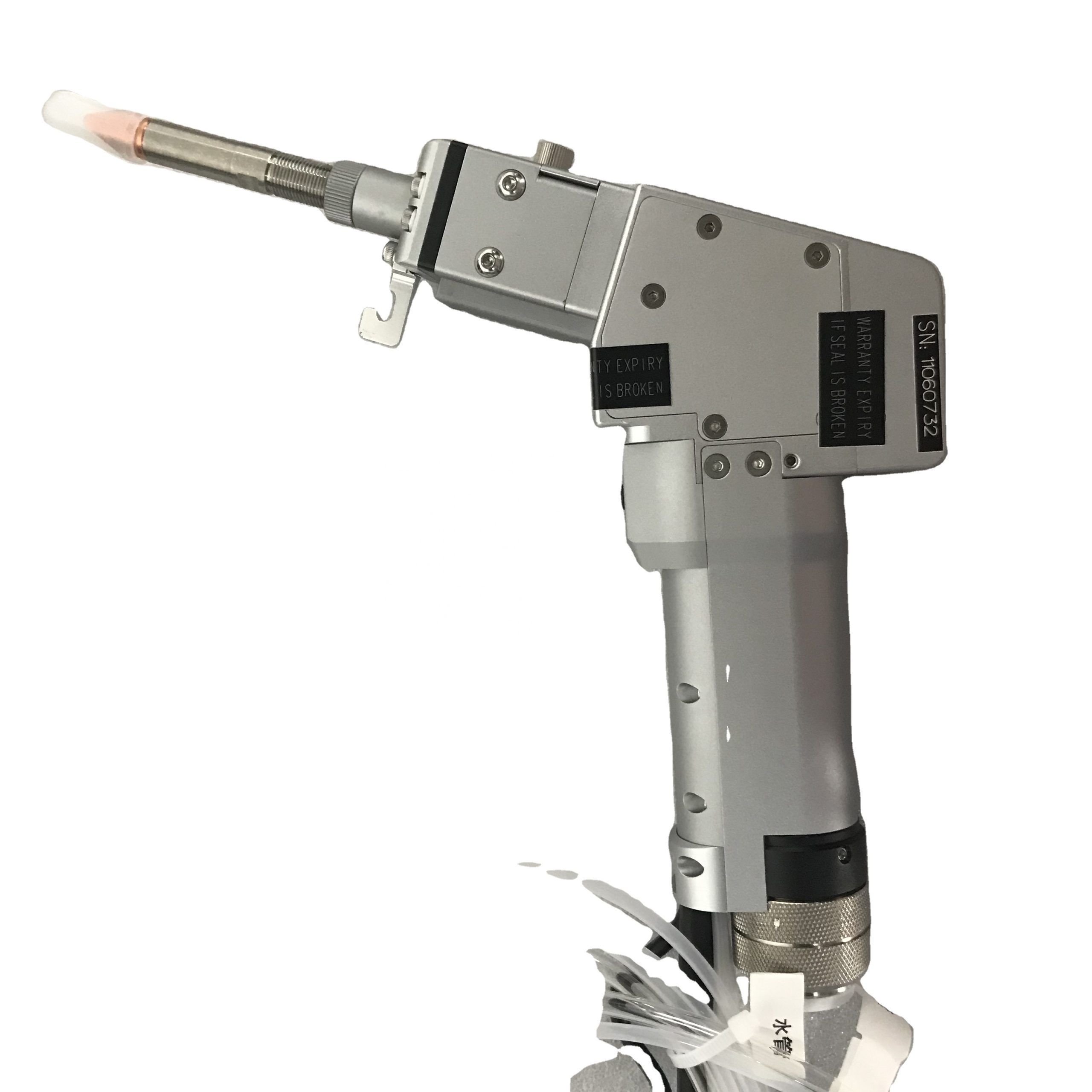

The hand-held laser welding machine has a lot advantages.Like simple operation,beautiful welding seam and no consumables.

The laser welding can perfectly replace the traditional argon arc welding and electric welding.Such as in the welding of stainless steel sheet, iron sheet, galvanized steel sheet and other metal materials.

Handheld laser welding is 2-10 times faster than conventional welding.A welding machine can save at least 2 workers a year.

For example,the weld seam is smooth and beautiful, reducing the subsequent grinding process, saving time and cost.

The laser welding workpiece has many advantages.It has no deformation, no welding and firm welding, and can reduce laser welding consumables.

Manual operation and maintenance of hand-held laser welding machine.

1.If We must train Hand-held laser welding machine operators to understand the use of system lights and buttons, familiar with the most basic equipment knowledge.

2.Check the working line slot before work, the wire is not damaged and exposed.And it is can’t prohibit to place tools on the water cooler.

3.It is strictly forbidden to place liquid objects and flammable articles on the control cabinet.

The temperature of the operation room must not exceed 25 ℃ no leakage and leakage,and no leakage of air, water and electricity.

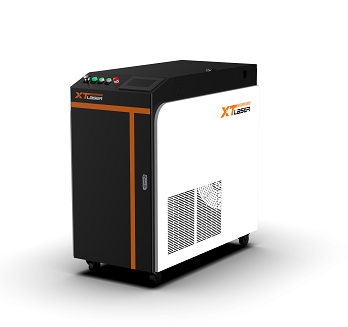

Maintenance of welding machine body.

1.Periodic testing.

2.Clean up the dust inside the welder regularly

3.Check the wiring of the electric power wiring regularly.

4.Replace defective parts during annual maintenance and inspection,and comprehensive repair work.

Such as outer casing and insulation deterioration,and regular Maintenance and inspection.

Regular Maintenance and inspection can reduce the occurrence of welding failure and extend the service life.

It can improve work efficiency,ensure the performance and safety of welding machine.

In fact, many customers said that the operation of welding machine is very simple.

That means when the basic work is ready, turn on the power and you can use it directly

How to operate the Handheld Welding Machine?Do you understand?

Hope it is helpful for you and if you have any questions,please feel free contact to us.

My email is xintian122@xtlaser.com

My phone is +86 17866940010(Whatsapp/Skype/Wechat)

This is our after-sales department.

This is our after-sales department. This is reception.

This is reception. This is our showroom.

This is our showroom.