MOPA laser marking machine M1 M6 for color laser marking(2) – Elena

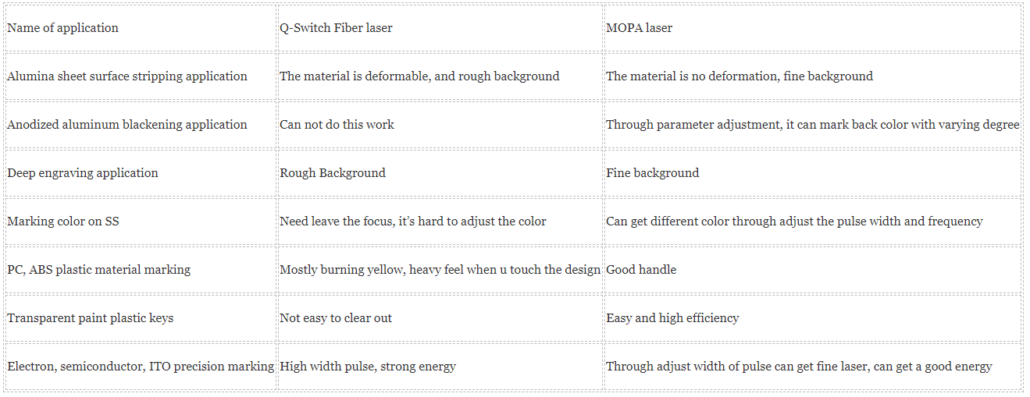

What is the application difference between a MOPA laser and a Q-switched laser?

1. Alumina sheet surface stripping application by MOPA laser marking machine

Today’s electronic products are getting thinner and lighter. Many mobile phones, tablets, and computers use thin aluminum oxide as the outer casing of the product. When we use the Q-switched laser to mark the conductive position on the thin aluminum plate, it will easy to deform the material. And a “convex package” is generated on the back surface, which directly affects the appearance of the appearance. However, the parameters of the smaller pulse width of the MOPA laser can make the material less deformable and the shading is more delicate and bright. This is because the MOPA laser uses a small pulse width parameter to make the laser stay in the material for a shorter time. And has enough energy to remove the anode layer. Therefore, for the processing of stripping the anode of a thin alumina plate, MOPA Lasers are a better choice.

2. Anodized aluminum blackening application by MOPA laser marking machine

We can use the laser to mark the black trademark, model, text, etc. on the anodized aluminum. We widely use it in electronic products by electronic manufacturers. Such as iphone, ipad in the past serveral years. On the mark, model, etc. used to mark the black mark. However, for this type of application, only MOPA lasers are currently available for processing. Since the MOPA laser has a wide pulse width and pulse frequency adjustment range, the parameters of the narrow pulse width and high frequency can be used to mark the black surface on the surface of the material. By different parameter combinations we can acquire different gray scale effects.

3. Electronic, semiconductor, ITO precision processing applications by MOPA laser marking machine

In electronics, semiconductors, and precision machining, it often requieres sophisticates scribing applications. Due to its own architecture, the Q-switched fiber laser cannot adjust the pulse width parameter, so the line drawn is difficult to be fine. The MOPA laser can flexibly adjust the pulse width and frequency parameters, which not only makes the line drawn fine, but also the edges appear smooth and not rough. Here are some typical application cases, as shown in the following table:

Welcome to contecme for asking more information

email: xintian128@xtlaser.com

https://www.xtlaser.com/product-item/mopa-laser-marking-machine/