34.Raycus fiber laser source common questions-Ella

The excellent characteristics of fiber laser make more and more customers

pay attention to replace the original processing methods with fiber laser solutions in metal processing.

With the localization of high-power fiber laser, the cost of various core devices has been greatly reduced,

so the selection threshold of high-power lasers has begun to disappear.

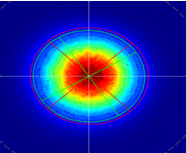

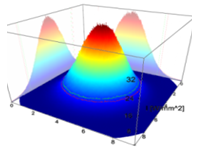

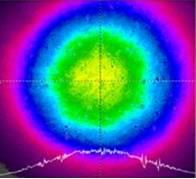

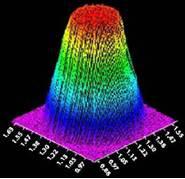

1.Single-mode and multi-mode beam quality comparison

In the cutting application, focus spot has a great influence on the cutting quality.

The core of the single-mode laser is relatively thin, the beam quality is better than multimode,

the energy distribution is Gaussian, the intermediate energy density is the highest,

and the three-dimensional map is a sharp circle. The shape of the mountain.

The core of a multimode laser is coarser than that of a single mode.

The energy distribution is smaller than that of a single mode.

The three-dimensional image is an average of a single-mode spot.

The three-dimensional image is an inverted cup.

From the edge steepness, the multimode ratio The single mode is steep.

2.Comparison of 1.5KW single mode and multimode laser with the same power:

1mm thin plate cutting speed single mode is 20% higher than multimode, the visual effect is similar,

but for 2mm, the speed advantage is gradually reduced.

Starting from 3mm, the speed and effect of high power multimode laser are very obvious.

Reflected, as shown below:

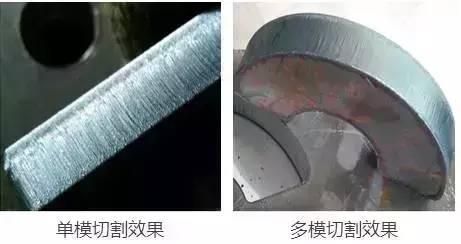

Left picture is Single Mode cutting effect, Right picture is Multimode cutting effect.

Therefore, the advantage of single mode is thin plate, the advantage of multimode is thick plate.

They are all a configuration of fiber laser. It is like a car.

The car is suitable for highway and off-road suitable for mountainous.

However, the car can also run the mountain, and the off-road can also run the road.

Therefore,the choice of multi-mode or single-mode depends on the processing needs of customers.

If you have more questions about laser cutting machine, contact us: