Fiber Laser cut sheet metal cutting machine-Wendy

Fiber Laser cut sheet metal cutting machine

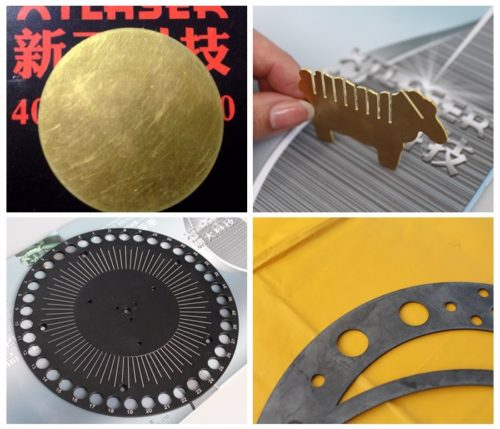

For the industrialize 21st century, the term Fiber laser cut sheet metal cutting machineis no longer unfamiliar. And it achieve an irreplaceable position in our industrial production field. However, different materials have different characteristics, and laser cutting is to cut the material by firing the high-temperature melting material. Therefore, the chemical reaction of laser cutting for different materials is different, so the material is laser process. When we do laser processing according to the characteristics of different materials, we will get more ideal processing results. Next, XT-LASER laser will popularize how to process more ideal laser cutting effects according to different characteristics of materials.

1. Titanium

The sheet cut with argon and nitrogen as process gases. Other parameters can reference to nickel-chromium steel. Both copper and brass have high reflectivity and very good thermal conductivity. Brass with a thickness of 1 mm or less can cut with nitrogen; copper with a thickness of 2 mm or less can cut, and oxygen must use for the processing gas. Copper and brass can only cut when a “reflective absorption” device is install on the system. Otherwise the reflection will destroy the optical components.

2. Synthetic materials

Keep in mind the dangers of cutting and hazardous substances that may be emitted when synthesizing materials. Machinable synthetic materials are: thermoplastics, thermosetting materials and elastomers.

3. Organic matter

Organic matter is at risk of fire in all organic cuttings (using nitrogen as a process gas or compressed air as a process gas). Wood, leather, cardboard and paper can be cut with a laser and the edges are burnt (brown).

To sum up

Laser cutting machines play a very important role in our work, especially for cutting some metal products. If you want to buy such a laser cutting machine, you must understand the laser cutting machine.With the development of technology, the field of laser cutting is becoming more and more extensive, and more and more materials are available.