Comparison of high power cutting Machine – Damon

1. Comparison of cutting speed of different power

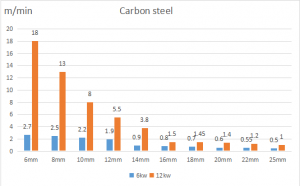

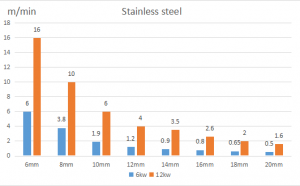

Comparison of cutting speed of 6 kw and 12 kw power.

The carbon steel cutting speed of 12 kw is 88%-567% faster than 6 kw.

The stainless steel cutting speed of 12 kw is 163%-289% faster than 6 kw.

Conclusion: You can cut more parts than other manufacturers in the same time.

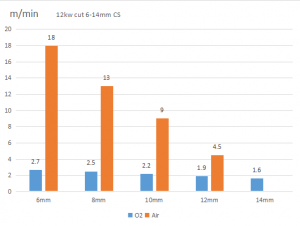

2. Advantages of cutting carbon steel by air

Cutting 12 kw of 6-14 mm Carbon steel with air 181% -567% more efficient than cutting with oxygen.

Conclusion: Air can be used when cutting 6-14 mm Carbon steel, save on oxygen by ensuring cutting speed.

3. Cutting effect

The high power laser cutting machine has a better cross-section and a smaller taper. At the same time, it can cut a wider thickness of the bright surface.

It can complete the bright surface cutting of 30 mm carbon steel. The finished product customer is more satisfied.

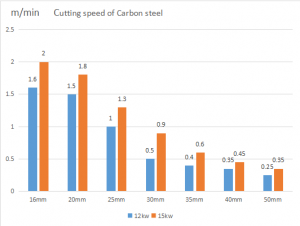

4. Comparison of 12 kw and 15 kw fiber laser cutting machine

The carbon steel cutting speed of 15 kW is 20% -50% faster than 12 kW.

The stainless steel cutting speed of 15 kW is 25% -67% faster than 12 kW.

So high power laser cutting machine can use air to cut thin plates, and the cutting effect can be guaranteed.

This will further reduce the cost of use and enhance the profitability of the company.

At present, some high power laser cutting machine manufacturers on the market are pursuing higher power, hoping to show their strength,

but ignore that high power is not only upgrading the laser power, but also the overall structure of the equipment.

For a high power laser cutting machine, higher power requires a more stable bed to ensure processing stability.

It can be seen from the comparison of cutting speed, high power laser cutting machine can expand the processing thickness range of plates.

Thus high power laser has a better space for development.