The CO2 laser marking machine+Karina

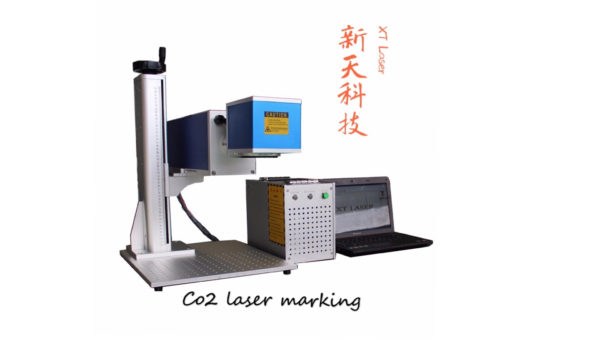

The CO2 laser marking machine

The CO2 laser marking machine uses a laser beam to mark permanent surfaces on a variety of different materials.

The effect of marking is to expose deep materials through evaporation of surface materials, thereby engraving exquisite patterns, trademarks, dates, logos or characters.

At present, CO2 laser marking machines are mainly using in some occasions requiring more precise and higher precision.

Used in food, medicine, wine, electronic components, integrated circuits (IC), electrical appliances, mobile communications, building materials, PVC pipe and other industries, the main advantage of CO2 laser marking machine and inkjet printer is that there is no consumables and permanent

Applicable materials and industrial applications

The CO2 laser marking machine can engrave a variety of non-metallic materials.

Used in garment accessories, pharmaceutical packaging, architectural ceramics, beverage packaging, fabric cutting, rubber products, shell nameplates, craft gifts, electronic components, leather fabrics, bamboo and wood products, label paper and other industries.

Typical application cases, such as laser marking of packaging boxes, paper printing, and printing of metal detonator casings.

Manual

Check the water circuit and circuit before turning it on. The boot sequence is:

Firstly, turn on the incoming power and turn on the key switch. At this time, the machine exhaust and the refrigeration system are energizing, and the ammeter shows a value of about 7A;

Secondly, wait 5 to 10 seconds, press the trigger button on the external control panel, the current meter display value is zero, after 3 to 5 seconds, the xenon lamp is ignited, and the ammeter displays the value 7A. (Refer to the laser power supply operating instructions);

Thirdly, turn on the galvanometer power supply;

Fourth, turn on the computer and call up the required marking file;

Fifth, adjust the laser power to the working current (10 ~ 18A), you can start marking;

After the marking is finished, reverse the power of each component in the above order:

Firstly, adjust the laser power supply operating current to a minimum (about 7A);

Secondly, turn off the computer;

Thirdly, turn off the galvanometer power supply;

Fourth, press the stop button;

Fifth, turn off the key switch;

Sixth, disconnect the incoming power.

Contact:Karina

Wechat&Whatsapp:008618206584205

Email:xintian103@xtlaser.com