Brief introduction of fiber laser marker-Angelina

Brief introduction of fiber laser marker

Although fiber laser marker is familiar in the market.

There are still some customers feel confused about it. they do not know how to use it.

Some do not know how to adjust the parameter etc.

Even some customers do not know what is the fiber laser marking machine.

Here will give some brief introduction for that.

1.Basic principles of fiber laser marker

First of all,Working principle of fiber laser marker.

It belongs to heat treatment, machine can mark signs on product by burn its surface.

Secondly,fiber laser marking machine is one of the most advanced laser marking equipment in the world nowadays.

The reasons are as below: stable output power, great optical model, excellent quality of laser beam, fast marking speed and best marking effect and efficiency.

Also, it is easy to operate, no consumption, low power consumption, and free maintenance.

Thirdly,it has more incomparable advantages.

That is better and thinner marking lines.

Fiber laser marking machine is capable of being applied into more advanced industries.

These industries need higher demand of depth, smoothness and precision, and perfectly meet requirement of consecutive working in industries.

At last,Wavelengthis 1064nm.

This decides that it can mark most of metal and nonmetal materials,enjoy wide application.

Fiber laser marking machine has many models for your choice,desktop, detached type, enclosure type, mini, portable, handheld etc.

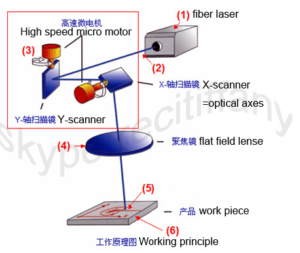

2.Functions of every part of fiber laser marker

1).Laser will come out from fiber laser source,the core components of the whole machine.

You can see it inside of the cabinet, it consists of laser module,fiber optic cable and resonant cavit.

Be careful the yellow optic cable.

Do not bending ,or the laser source will stop working.

2) Laser come out from fiber laser source,then will arrive at laser head,

Laser head , inside, there is two small mirrors (X axis and Y axis).

Therefore laser beam can be focused and reflected on workpieces.

3) Field lens: It controls marking area, our standard marking area include:50*50 110*110 175*175 200*200 300*300mm.etc.

4) Laser beam path: Laser head could connect with it, inside the path,

And then laser beam go through it,inside the laser path,there have an red indicator near the laser head.

5) Lifting table: adjust height of laser head and laser beam path, so you can adjust focus distance between laser head and workpieces

6) 2D work table(optional):On its surface, it has lines of screw hole, mainly for fixing workpiece.

7) Machine has clear function buttons, main power switch, red spot, scanner lens,.etc.