Handheld welding machine for 1-5mm metal-Ivy

Handheld welding machine for 1-5mm metal

Recently,More and more customers asking for Handheld welding machine for 1-5mm metal,now in the market,1kw and 1.5kw gain more popular,here some details based on 1kw.

Price:

| Quotation | FOB Qingdao $12500

|

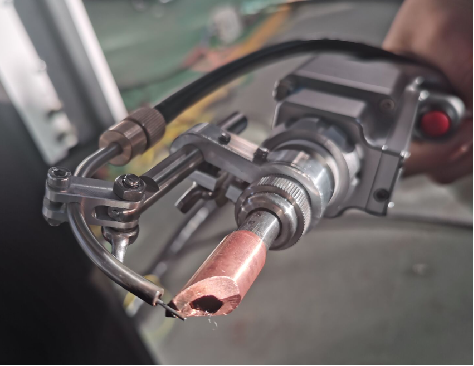

| Machine Name | 1kw Handheld Laser Welding Machine with Wobble Head |

| Machine Model | XT-W1000 |

| Wobble Head |  |

| Laser Source | 1kw Raycus/IPG |

Technical Parameters

| Machine Name | Hanheld Laser Welding Machine |

| Laser Power | 1KW |

| Electric Power | 7.5kw |

| Cooling mode | Water Cooling |

| Laser pulse Frequency | 1-20HZ |

| Pulse width | 0.1-20ms |

| Adjusted spot range | 0.1-3.0mm |

| Spot size | 0.2-3.0mm |

| Minimum welding pool | 0.1mm |

| Machine dimension | 62.5*109*175cm |

| Water tank | Inbuilt model |

| Grand weight | 250kgs |

| Optical Fiber | 50um,10M |

| Continous Working Time | 24 hours |

| Comllimation Length | F=50mm |

| Laser source | Raycus/IPG |

Advantages of laser welding wobble head:

1. The process that the conventional head can not complete, the dithering head only needs to use about 70% of the power, so that the cost of the laser can be saved.

2. Wobble welding back and forth through the galvanometer motor, so that the bubbles with large impurities can reduce bubbles, frying, splashing, etc.

3. In the case of irregular gaps, the requirements for the fixture can be reduced. The conventional oscillating head welding gap is generally 0.2 mm, and light exceeding this width directly passes through. The width of the gap that can be welded by the oscillating head can reach 0.5mm. but the conventional welding head can only be welded to 0.2mm. There is no galvanometer motor in the welding head, so there is no swing. The welding effect is not good, the welding process is limited.

Wechat/whatsapp 0086 17864184107

xintian108@xtlaser.com