“Small and Beautiful” Laser Cutting Nozzle, Which One Is Right for You?—Winnie

Active Gas Laser Cutting

Energy from the laser beam heats the material (mild steel) to above the ignition temperature in the reactive gas (O2).

Fe+½O2→FeO

Combustion-process Fuels the Burning of Iron Oxide

Once the kerf has been opened, material removal is from a nearly vertical erosion front (thin molten layer). Absorption of laser energy is predominantly at this liquid layer during the cutting processing. The layer loses heat by vaporisation, by ejection of liquid material at the lower surface, by conduction and by melting of solid material as the cut advances. In order to ensure the quality of the workpiece and the efficiency of the process, the selection of the proper conditions is very important, such as laser power, cutting parameters, cutting head and nozzle.

Striations-The slow cutting speed will cause the local thermal accumulation,which will lead to rough striations even side burns.

The Overview of Laser Cutting Nozzle

The nozzle is very important in laser cutting. Its main purpose is to deliver a gas jet such that the heat generated by the laser beam (and the resulting melt & vapour) is blown away, leaving a clean cut.

If the nozzle is poorly designed (& maintained), the gas jet will not have the required velocity or directional stability to remove the molten material.

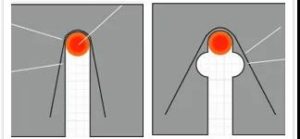

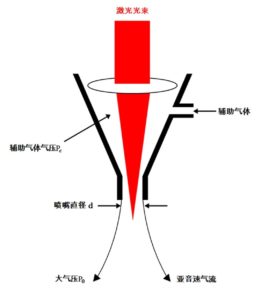

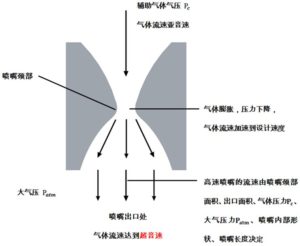

Firstly, there are two basic designs: ‘Low Speed’ (gas velocity less than speed of sound) and ‘High Speed’ (velocities around the speed of sound). Secondly, there are many factors that affect nozzle performance nozzles, such as chamber pressure , nozzle diameter, internal shape, so nozzle exit shape and nozzle material.

Low Speed Nozzle VS High Speed Nozzle

Low Speed Nozzle

Laval High Speed Nozzle

Why high speed LC nozzles?

Some materials such as stainless steel and aluminium alloy are difficult to cut because their molten material is viscous and cannot be easily removed with low gas speeds.

High speed nozzles work on the same principle as a rocket or jet engine exhaust. The gas expands, pressure drops and the gas velocity accelerates to the design velocity at the nozzle throat region and accelerates to the supersonic gas velocity at the nozzle exit. The design velocity is determined by throat area, exit area, gas pressure, atmospheric pressure, nozzle inter shape and nozzle length.

The gas pressure along the axis of the jet can vary a great deal with changing of the stand-off distance in the low speed case and variation in pressure on the work-piece surface will affect the ability of the gas jet to remove molten material at the cut front.

Relationship between Surface Quality and Nozzle

Nozzle temperature: The high temperature of the nozzle will affect the capacitance of the ceramic ring so cause the instable stand-off distance, and which will lead to the uncontrollable cutting quality during the production.

Carbon steel oxygen bright surface cutting stable processing recommended nozzle selection

| thickness(mm) | recommend |

| 12~14 | 1.2E~1.4Emm |

| 16~20 | 1.4E~1.6Emm |

| 22~30 | 1.6E~1.8Emm |

Double-layer high-speed nozzle cutting effect

16mm CS Q235B

18mm CS Q235B

20mm CS Q235B

25mm CS Q235

Single-layer high-speed nozzle

30mm CS Q235B

cutting speed 0.8~1m/min